2D Pellet Snacks Food Process Line

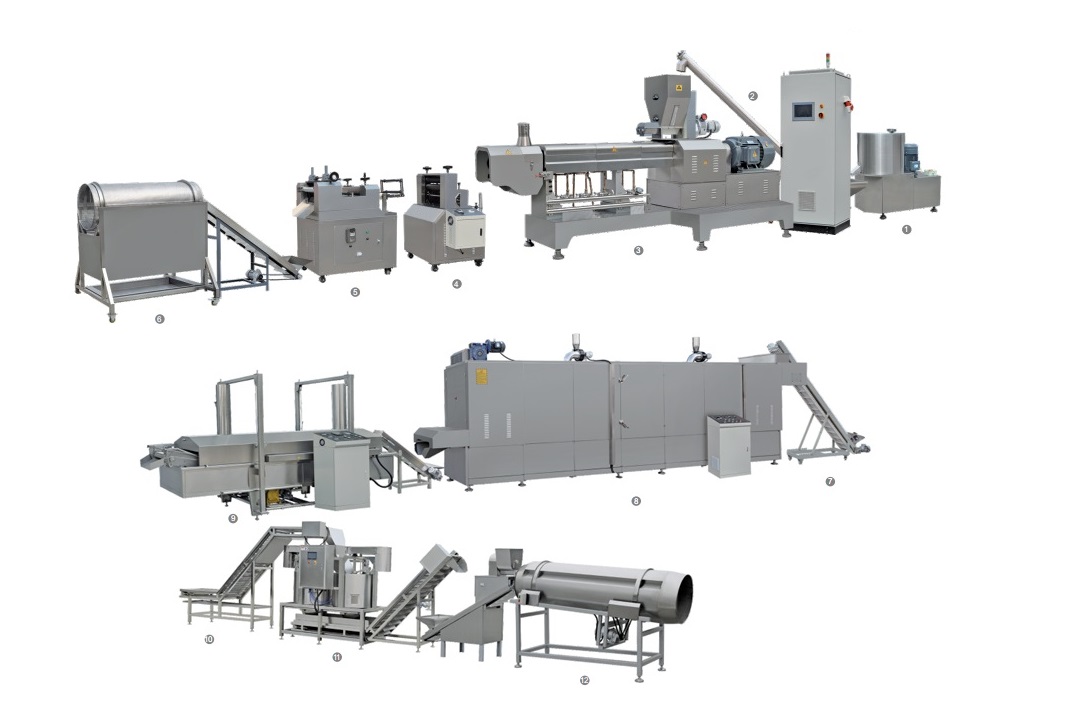

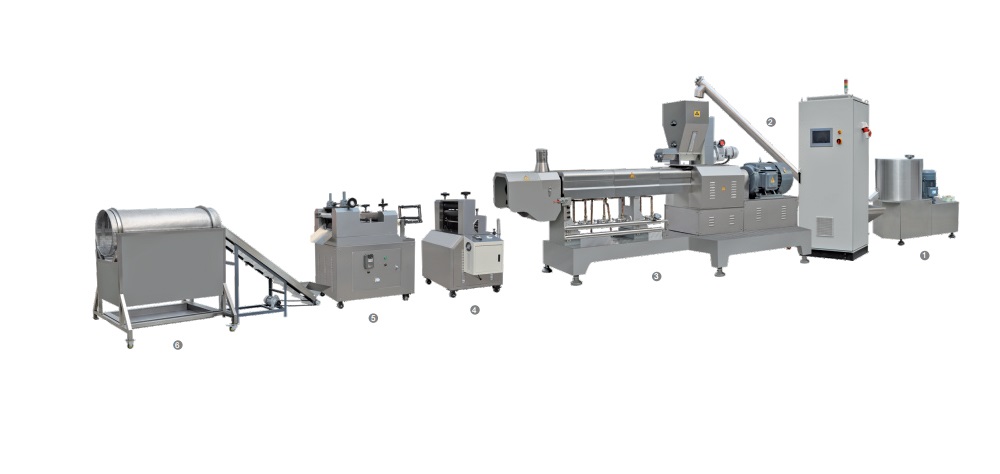

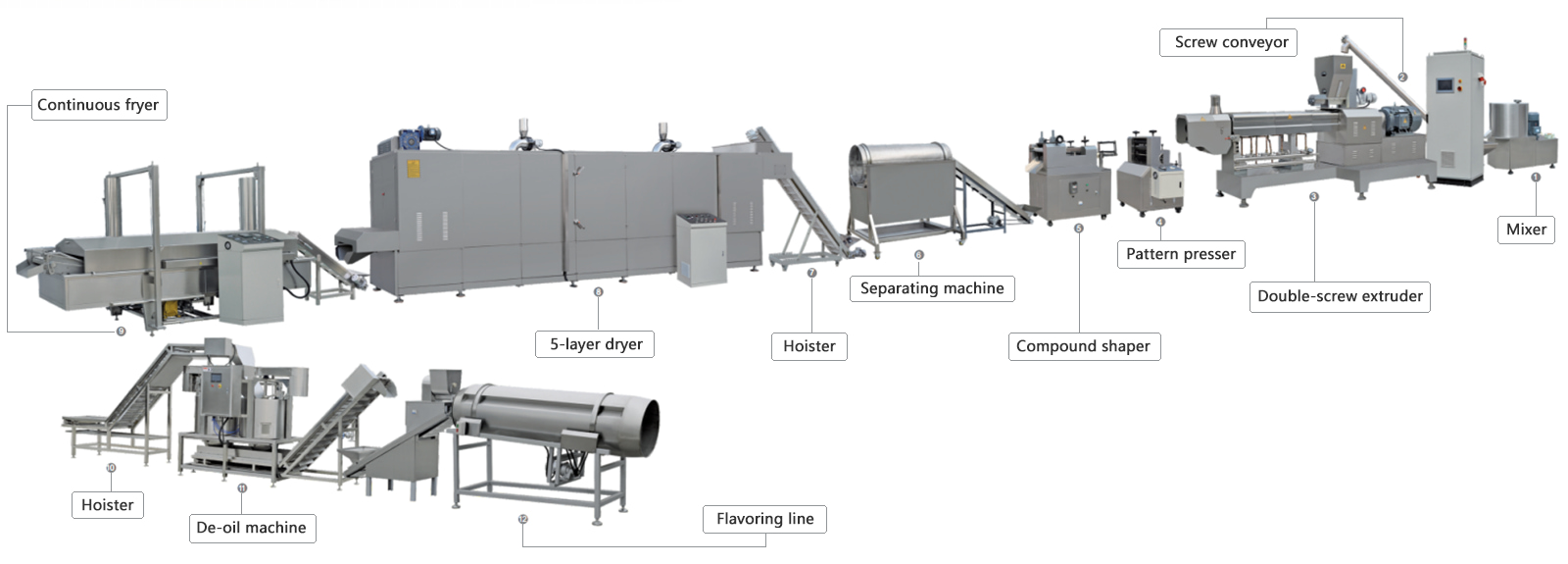

2D Pellet Snacks Food Process Line consists of:

1. Mixer

2. Screw elevator

3. Twin screw host/Double screw extractor

4. Embossing machine/Pattern presser

5. Compound shaper

6. Separating machine

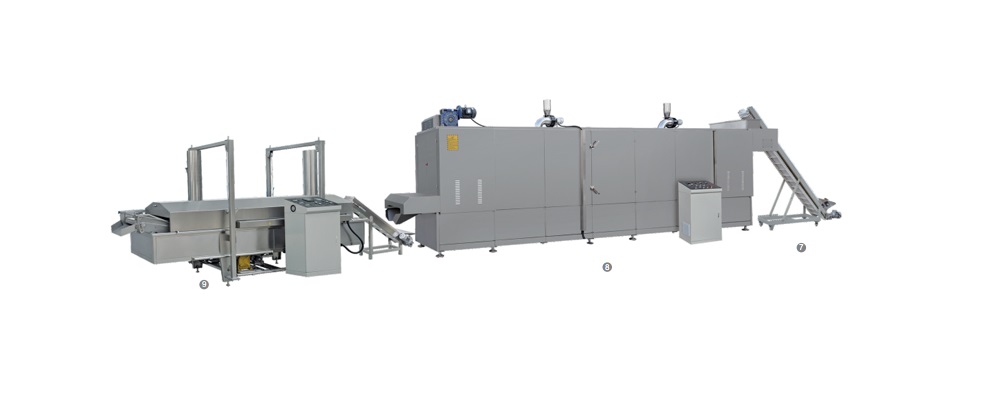

7. Hoist/Hoister

8. Oven/5-layer layer

9. Continuous fryer

10. Hoist/Hoister

11. Oil slinger/De oil machine

12. Automatic flavoring line

Cooking, lowering, and so on techniques to offer spiral, tube, onion ring, waved chips, and so forth snack pellets. which encompass crisp peas, shells, screws, square tubes, round tubes, and waves. also can equip with a sample urgent tool and compound device to provide bugles, net crispy, pani puri, and masses of diverse three-d snack pellets. then through the manner of drying, frying, and flavoring, the snack pellet can be made to be crispy, and colorful nicely now and eaten after times extrusion of puffed food.

The process line makes use of wheat flour, corn flour, corn starch, tapioca starch, and potato starch as raw materials.

This process line is characterized with the aid of the way of the use of a selected method, rational configuration, excessive automation, and sturdy regular common overall performance. it may give up steaming, extrusion, and shaping in a single step without a boiler. and combinations of the unit screw and unique manipulation of processing, gain better extremely good and numerous products with a choice for raw cloth.

Raw Materials of 2D Pellet Snacks Food Process Line:

Wheat flour, potato starch, potato flour, corn starch, cassava starch, and so forth.

Processes of 2D Pellet Snacks Food Process Line:

Mixer--extruder--pulling cutter-compound shaper--curler drum--vibration cooler--hoister--dryer--fryer--flavoring

Technical parameters of 2D Pellet Snacks Food Process Line:

Model | HX65 | HX70 | HX85 |

Installed Power | 75kw | 135kw | 240kw |

Power Consumption | 55kw | 95kw | 180kw |

Capacity | 120-200kg/h | 200-300kg/h | 400-500kg/h |

Dimension | 28*2.6*2.4m | 36*3.5*3.0m | 38*3.8*3.5m |

Packaging and shipping of 2D Pellet Snacks Food Process Line:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation; In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible