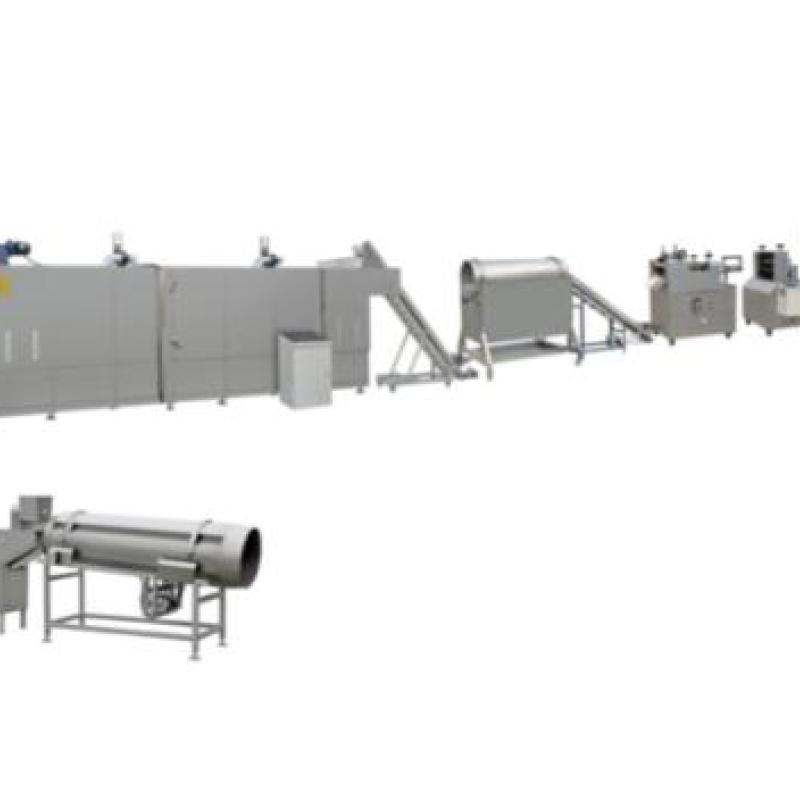

Nutritional Powder Food MachineryNutritional Powder Food Machinery is particularly for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, and so on extruding and inflating. Thru extruding, inflating, drying, crushing, and mixing, it could produce many varieties of vitamin powder, such as toddler rice powder, sesame paste, beans powder, and so on. Functions of Nutritional Powder Food Machinery:1). Nutritional Powder Food Machinery should finish the procedures routinely from the feeding to the stop.

Contact Now

Dog Cat Food Making Machine strains especially use maize, fish powder, meat powder, and some meal components due to the main uncooked materials, via blending, extruding, roasting, and flavoring to get the final puffed domestic dog food.The Dog Cat Food Making Machine has been taken care of, one is a dry kind dog food production line, and the opposite is a moist kind meals production plant, wet kind is ready with a boiler that could constantly gift warm steam.It could produce all forms of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog,

Contact Now

Dog Food Making Machine mainly uses maize, fish powder, meat powder, and some food additive as the main raw materials, through mixing, extruding, roasting, and flavoring to get the final puffed pet food.Dog food production line has two types, one is a dry type canine food production line, and the other is wet kind meals manufacturing plant, moist kind is equipped with a boiler that can continuously present hot steam.It may produce all kinds of feeds and meals as manufacturing floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, etc, and pet meals like dog meals, cat fo

Contact Now

Pet chews take starch from many types of different materials with medical configurations and emerge as extruded from a co-extruder, it can be made into different kinds of shapes such as stick, bone, bi-color, bi-flavor, twists, middle-filling, and so forth.This form of the meal no longer simplest provides protein, fats, diet, and nutrients for dogs but moreover fulfills the dog nature interest.

Contact Now

Pet chews take starch from many types of different materials with medical configurations and emerge as extruded from a co-extruder, it can be made into different kinds of shapes such as stick, bone, bi-color, bi-flavor, twists, middle-filling, and so forth.This form of the meal no longer simplest provides protein, fats, diet, and nutrients for dogs but moreover fulfills the dog nature interest.

Contact Now

Cat Food Making Machine strains in particular use maize, fish powder, meat powder, and a few meal components due to the precept raw materials, through blending, extruding, roasting, and flavoring to get the very last puffed home canine food.The cat food making machine has been taken care of, one is a dry type dog meals production line, and the opportunity is a moist kind food manufacturing plant, moist type is ready with a boiler that could constantly present warm steam.It may produce all sorts of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach,

Contact Now

Dog chews take starch from many kinds of exceptional substances with clinical configurations and turn out to be extruded from a co-extruder, it is able to be made into one in every of the type styles of shapes which consist of stick, bone, bi-shade, bi-flavor, twists, center-filling, and so forth.This type of meal no longer best offers protein, fat, vitamins, and nutrients for puppies but additionally satisfies the dog nature hobby. it has the subsequent functions: robust tooth, a clean mouth, and enamel. Benefits of Pet Dog Chew Process Line:1.

Contact Now

Pet Food Making Machine strains in particular use maize, fish powder, meat powder, and a few meal components due to the precept raw materials, through blending, extruding, roasting, and flavoring to get the very last puffed home canine food.Pet Food Making Machine has been taken care of, one is a dry type dog meals production line, and the opportunity is a moist kind food manufacturing plant, the moist type is ready with a boiler that could constantly present warm steam.It may produce all sorts of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach,

Contact Now

Puppy chews take starch from many kinds of first-rate materials with clinical configurations and grow to be extruded from a co-extruder, it is able to be made into one in every one of the typical sorts of shapes which encompass stick, bone, bi-coloration, bi-taste, twists, middle-filling, and so on.This type of meal not fantastically gives protein, fat, vitamins, and vitamins for dogs but moreover satisfies the dog nature interest. it has the subsequent functions: robust teeth, a smooth mouth, and a tooth. Benefits of Automatic pet chewing dog cat food production line:1.

Contact Now

Pet chews take starch from many kinds of different substances with scientific configurations and become extruded from a co-extruder, it can be made into one of the kind sorts of shapes which include stick, bone, bi-color, bi-taste, twists, center-filling, and so forth.This kind of meal no longer handiest offers protein, fat, nutrition, and nutrients for puppies but also fulfill the dog nature hobby. it has the subsequent features: sturdy enamel, an easy mouth, and enamel. Advantages of Pet Dog Chews Machine:1.

Contact Now

Dog Cat Pet Food Extruder MachineDog Cat Pet Food Extruder Machine especially use maize, fish powder, meat powder, and a few meal components due to the main uncooked materials, via blending, extruding, roasting, and flavoring to get the very last puffed home dog food.The pet food extruder machine has been sorted, one is a dry type canine meals manufacturing line, and the opposite is a moist type food production plant, wet type is prepared with a boiler that would continuously present heat steam.It is able to produce all types of feeds and food as production floating feeds for aqua, catfish, go

Contact Now

Dry Pet Food Making Machine particularly use maize, fish powder, meat powder, and a few meal additives due to the principle raw materials, via mixing, extruding, roasting, and flavoring to get the final puffed home canine meals.The pet food maksing machine has been looked after, one is a dry kind dog food production line, and the alternative is a wet kind meals production plant, moist type is ready with a boiler that would continuously gift heat steam.It may produce all types of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, and so o

Contact Now

Puppy meal manufacturing strains especially use maize, fish powder, meat powder, and a few meal additives because of the major raw materials, via blending, extruding, roasting, and flavoring to get the final puffed doggy food.The pet meals processing line has been sorted, one is a dry type dog food manufacturing line, and the opposite is a wet kind food manufacturing plant, moist type is ready with a boiler that can continuously gift warm steam.It is able to produce all forms of feeds and food as manufacturing floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, and so

Contact Now

Pet chews take starch from many forms of remarkable substances with clinical configurations and emerge as extruded from a co-extruder, it could be made into one in each of the typical kinds of shapes which encompass stick, bone, bi-shade, bi-taste, twists, middle-filling, and so forth.This sort of meal now not exceptionally gives protein, fat, vitamins, and nutrients for puppies but moreover satisfies the dog nature interest. it has the subsequent features: robust teeth, a smooth mouth, and teeth. Advantages of Pet Chews Making Machine:1.

Contact Now

Macaroni Fried Food Making Machine adopts tough wheat flour or corn starch as the primary fabric to supply a spread of second-extruded food in awesome shapes which may be famous within the market, which includes crispy peas, shells, screws, square tubes, spherical tubes, wave, and so on. the goods appear like glittering, translucent smooth, delightful, and taste scrumptious after cooking.Features of Macaroni Fried Food Making Machine:1).

Contact Now

Breakfast Cereal Food Making Machine commonly uses corn powder and unique cereals due to the essential raw fabric, through mixing, extruding, baking, coating, drying, and cooling, to get crispy corn flakes. the very last product cornflake or breakfast cereal is a very delicious breakfast cereal that is one form of a dietary handy meal with the benefits of tough steeped broken and robust grain flavor. after being milled flat, the final product is clean to be cooked and digested. it can be eaten like a snack and be moreover eaten with milk or espresso as properly.

Contact Now

Corn flakes food-making machine generally makes use of corn powder and different cereals because of the fundamental uncooked material, via mixing, extruding, baking, coating, drying, and cooling, to get crispy corn flakes. the final product cornflake or breakfast cereal is a completely scrumptious breakfast cereal that is one shape of a nutritional handy meal with the benefits of tough steeped damaged and strong grain taste. after being milled flat, the very last product is smooth to be cooked and digested. it may be eaten like a snack and be additionally eaten with milk or coffee as well.

Contact Now

Macaroni Pasta Making MachineMacaroni pasta making machine only needs to change the mold to process and produce macaroni foods of various shapes, which are very versatile. The macaroni foods produced are high in nutrients and rich in taste, which are deeply loved by consumers. As a staple food, the consumption of macaroni is very large. Therefore, macaroni has a very broad development prospect. And the profit contained in the macaroni industry is also very considerable. The technological process of the Macaroni Pasta Making Machine:1.

Contact Now

Baby Food Nutrition Powder Making Machine is mainly for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, and so on extruding and inflating. Thru extruding, inflating, drying, crushing, and combining, it can produce many kinds of vitamin powder, along with baby rice powder, sesame paste, beans powder, and so on. Features of Baby Food Nutrition Powder Making Machine:1). Toddler meals /changed starch production line must stop the procedures mechanically from the feeding to the end.

Contact Now

Corn Flakes Breakfast Cereal Making MachineCorn flakes breakfast cereals making machine typically makes use of corn powder and other cereals as the principal uncooked cloth, thru blending, extruding, baking, coating, drying, and cooling, to get crispy corn flakes. the very last product cornflake or breakfast cereal is a very delicious breakfast cereal this is one type of dietary handy meal with the blessings of tough to be steeped broken and strong grain flavor. after being milled flat, the very last merchandise is clean to be cooked and digested.

Contact Now

Nutritional Rice Making Machine is based on food dietary call for and superior technology. it has the benefits of excessive automatic and saving power.The line is advanced to avoid the lack of nutritional elements within the rice that's made thru conventional rice processing.It adopts rice, millet, black rice, buckwheat, and so on. as important substances. after the approaches of extruding, cooking, and shaping, the substances can be made into bolstered rice, golden rice, buckwheat rice, solanum tubers rice, and so forth.

Contact Now

Puffed Corn Snacks Food Making Machine is an advanced and efficient system used in the food industry for manufacturing puffed snacks. It is specifically designed to automate the production process, optimizing efficiency and ensuring consistent quality of the snacks.The machine consists of several key components, each contributing to a smooth and streamlined operation. Firstly, there is a raw material mixer, which blends the necessary ingredients to create the base mixture for the puffed snacks.

Contact Now

Baby Food /Modified Starch Production Line is mainly for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, etc extruding and inflating. Through extruding, inflating, drying, crushing, and mixing, it could produce many kinds of nutrition powder, such as baby rice powder, sesame paste, beans powder, and so on. Double-screw food extruder can cook the materials with high pressure and high temperature. But it does not destroy the nutrients of the natural cereals.Functions of Modified Starch Making Machine:1).

Contact Now

Fortified Rice Making Machine is based on food nutritional demand and advanced generation. it has the blessings of excessive automation and saving electricity.The machine is advanced to avoid the loss of dietary factors inside the rice that is made via conventional rice processing.It adopts rice, millet, black rice, buckwheat, and so on. as major substances. After the approaches of extruding, cooking, and shaping, the materials can be made into reinforced rice, golden rice, buckwheat rice, solanum tubers rice, and so on.

Contact Now