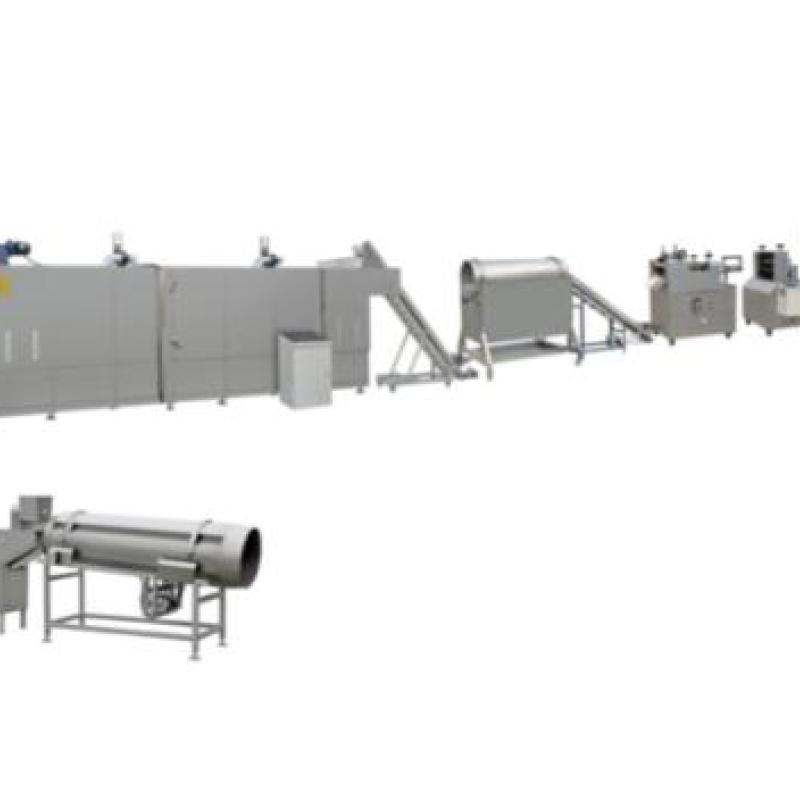

Doritos Crispy Chips Sala Production LineFeatures of Doritos Crispy Chips Sala Production Line:Doritos Crispy Chips Sala Production Line corn powder or flour, vegetable oil, salt, and water as the main raw material uses screw extrusion molding technology combined with the shapes of the extrusion die extrusion and then fried to flavored salad, banana chips, pizza volume realistic shell cakes, cat ears crisp, “snail” a variety of shapes and flavors of fried pasta food, product modeling, the organization is delicate, crisp taste.Extrusion products can be fried, without drying, the productio

Contact Now

Doritos Corn Chips Snacks Processing Line corn powder or flour, vegetable oil, salt, and water due to the truth that the primary uncooked material uses screw extrusion molding technology blended with the shapes of the extrusion die extrusion after which fried to flavored salad, banana chips, pizza quantity practical shell cakes, cat ears crisp, “snail” a diffusion of shapes and flavors of fried pasta meals, product modeling, the business enterprise organization is touchy crisp flavor.Extrusion products can be fried, without drying, the manufacturing way is easy, and the small funding in m

Contact Now

Doritos Corn Chips Snacks Food Extruder corn powder or flour, vegetable oil, salt, and water due to the fact the number one uncooked fabric makes use of screw extrusion molding generation mixed with the shapes of the extrusion die extrusion after which fried to flavored salad, banana chips, pizza quantity sensible shell desserts, cat ears crisp, “snail” a spread of shapes and flavors of fried pasta meals, product modeling, the business organization is sensitive crisp flavor.Extrusion products can be fried, without drying, the production way is straightforward, and the small investment in machi

Contact Now

Doritos Tortilla Corn Chips Food Machine corn powder or flour, vegetable oil, salt, and water due to the truth that the number one raw cloth uses screw extrusion molding technology combined with the shapes of the extrusion die extrusion after which fried to flavored salad, banana chips, pizza amount sensible shell cakes, cat ears crisp, “snail” a variety of shapes and flavors of fried pasta meals, product modeling, the business enterprise organization is touchy crisp flavor.Extrusion merchandise can be fried, with out drying, the producing manner is simple, and the small investment in machines

Contact Now

Doritos Chips Making MachineDoritos Chips uses corn powder, corn starch, and rice powder as main materials, and then mixed with water, vegetable oil, and salt. They are extruded and compounded into triangle, round, square shapes, or others by Doritos Chips Making Machine. After being fried and flavored, the final snacks will be quite crispy, spraying some seasoning powder will make them more savory and delicious. And During compound shaping, some waste edges will be cut down, but they can be reused by grinding them into powder and filling in the raw materials in a certain proportion.

Contact Now

Cooking, reducing, and so on strategies to provide spiral, tube, onion ring, waved chips, and so on snack pellets. which includes crisp peas, shells, screws, rectangular tubes, round tubes, and waves. can also equip with a sample urgent tool and compound device to offer bugles, net crispy, pani puri, and lots of other 3-d snack pellets.

Contact Now

Fried Snacks Extruder Production Line corn powder or flour, vegetable oil, salt, and water because the primary uncooked fabric uses screw extrusion molding generation blended with the shapes of the extrusion die extrusion and then fried to flavored salad, banana chips, pizza quantity practical shell cakes, cat ears crisp, “snail” a selection of shapes and flavors of fried pasta meals, product modeling, the agency is delicate, crisp flavor.Extrusion merchandise may be fried, without drying, the production manner is easy, and the small funding in machines is the right desire for small and medium

Contact Now

Puffyed Snacks Food Production Line is specially designed according to the process of deep-fried food, which is applicable to the continuous automatic snack fryer industry. It can produce fried chicken, French fries, sweet potato chips, beans, doughnuts, and other foods with good color effect, high output, energy saving, durability, and hygiene.Features of Puffyed Snacks Food Production Line:1). Puffyed Snacks Food Production Line adopts a double mesh belt to convey food.

Contact Now

Fried Snacks Food Production Line corn powder or flour, vegetable oil, salt, and water as the primary uncooked material uses screw extrusion molding era combined with the shapes of the extrusion die extrusion and then fried to flavored salad, banana chips, pizza volume sensible shell cakes, cat ears crisp, “snail” a selection of shapes and flavors of fried pasta meals, product modeling, the corporation is delicate, crisp taste.Extrusion merchandise can be fried, without drying, the manufacturing process is simple, and the small investment in system is the right choice for small and medium corp

Contact Now

Cooking, reducing, and so on procedures to provide spiral, tube, onion ring, waved chips, and so on snack pellets. inclusive of crisp peas, shells, screws, rectangular tubes, round tubes, and waves. can also equip with a sample pressing device and compound system to provide bugles, internet crispy, pani puri, and ma:ny other 3-D snack pellets.

Contact Now

Corn flakes breakfast cereals processing line usually makes use of corn powder and other cereals as the predominant uncooked fabric, through blending, extruding, baking, coating, drying, and cooling, to get crispy corn flakes. the very last product cornflake or breakfast cereal is a very delicious breakfast cereal this is one form of a dietary handy meal with the benefits of difficult steeped damaged and sturdy grain flavor. after being milled flat, the very last merchandise is smooth to be cooked and digested.

Contact Now

Corn Puffyed Snacks Making MachineCapabilities of Corn Puffyed Snacks Making Machine:Corn Puffyed Snacks Making Machine can do the works of raw materials practice, extrusion, center filling, shaping, lowering, coating, and flavoring at a time. this approach line is characterized by using superior technical, rational configuration, immoderate automation, and robust average overall performance.It could produce all kinds of inflating meals, along with middle-filling snack food, filling biscuits, nutrition breakfast, corn flakes, stuff, rice bread, rolling snacks, and so on, and so forth.

Contact Now

Corn flakes /breakfast cereals production line typically uses corn powder and other cereals as the main raw fabric, thru blending, extruding, baking, coating, drying, and cooling, to get crispy corn flakes. the very last product cornflake or breakfast cereal is a totally delicious breakfast cereal that is one kind of nutritional handy meal with the advantages of tough to be steeped broken and robust grain taste. after being milled flat, the very last products are clean to be cooked and digested. it is able to be eaten like a snack and be additionally eaten with milk or espresso as nicely.

Contact Now

Capabilities of Corn Puffyed Snacks Food Extrusion Machine:Corn Puffyed Snacks Food Extrusion Machine can do the works of raw substances practice, extrusion, center filling, shaping, lowering, coating, and flavoring at a time. this technique line is characterized by using superior technical, rational configuration, immoderate automation, and strong overall performance.It is able to produce all varieties of inflating meals, along with middle-filling snack food, filling biscuits, nutrition breakfast, corn flakes, stuff, rice bread, rolling snacks, and so forth, and so forth.

Contact Now

Puffed Corn Snacks Food Making Machine is an advanced and efficient system used in the food industry for manufacturing puffed snacks. It is specifically designed to automate the production process, optimizing efficiency and ensuring consistent quality of the snacks.The machine consists of several key components, each contributing to a smooth and streamlined operation. Firstly, there is a raw material mixer, which blends the necessary ingredients to create the base mixture for the puffed snacks.

Contact Now

Cooking, lowering, and so on strategies to provide spiral, tube, onion ring, waved chips, and so on snack pellets. which consist of crisp peas, shells, screws, square tubes, spherical tubes, and waves. also can equip with a pattern pressing device and compound device to offer bugles, internet crispy, pani puri, and loads of various three-d snack pellets.

Contact Now

Cooking, lowering, and so on techniques to offer spiral, tube, onion ring, waved chips, and so forth snack pellets. which encompass crisp peas, shells, screws, square tubes, round tubes, and waves. also can equip with a sample urgent tool and compound device to provide bugles, net crispy, pani puri, and masses of diverse three-d snack pellets.

Contact Now

Textured vegetable protein(TVP) production line is developed and synthetic on the base of our experience mixed with advanced machines from foreign countries. the texture of soy protein has high nutrients, seems and tastes like meat, and has an experience of mastication. easy to soak up oil, water, and flavor; textured soybean protein is extensively used within the meat products industry, fast meals production, deepfreeze meals production, and all sorts of vegetarian snacks and food.Textured soy protein( tsp) is made from defatted soy flour, that's low-oil soy fabric.

Contact Now

Textured vegetable protein(TVP) manufacturing line is advanced and manufactured on base of our experience blended with superior machines from overseas international locations. They feel soy protein has excessive vitamins, looks and tastes like meat, and has an experience of mastication. clean to soak up oil, water, and flavor; textured soybean protein is extensively used in the meat merchandise industry, speedy meal production, deepfreeze food production, and all varieties of vegetarian snacks and meals.Textured soy protein( tsp) is made from defatted soy flour, which is low-oil soy cloth.

Contact Now

Modified starch production line is especially for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, and so on extruding and inflating. Through extruding, inflating, drying, crushing, and combining, it is able to produce many forms of nutrient powder, including child rice powder, sesame paste, beans powder, and so forth. Specification of Modified Starch Production Line:ModelHX65HX70HX85Installed Power77kw108kw150kwPower Consumption50kw75kw100kwCapacity100-150kg/h200-260kg/h400-500kg/hDimension19*1.3*2.2m21*1.3*2.2m30*1.3*2.2mFeatur

Contact Now

Cooking, lowering, and so on strategies to offer spiral, tube, onion ring, waved chips, and so forth snack pellets. consisting of crisp peas, shells, screws, rectangular tubes, spherical tubes, and waves. also can equip with a sample urgent tool and compound device to offer bugles, net crispy, pani puri, and lots of other 3-d snack pellets.

Contact Now

Baby Modified Starch Production Line is mainly for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, and so on extruding and inflating. Thru extruding, inflating, drying, crushing, and combining, it can produce many kinds of vitamin powder, along with baby rice powder, sesame paste, beans powder, and so on. Functions of Baby Modified Starch Production Line:1). Toddler meals /changed starch production line must stop the procedures mechanically from the feeding to the end.

Contact Now

Textured vegetable protein(TVP) production line is advanced and synthetic on the base of our revel in combined with advanced machines from foreign nations. They feel soy protein has excessive nutrition, looks and tastes like meat, and has an experience of mastication. clean to soak up oil, water, and taste; textured soybean protein is extensively used within the meat merchandise enterprise, fast food production, deepfreeze meal manufacturing, and all types of vegetarian snacks and food.Textured soy protein( tsp) is crafted from defatted soy flour, that's low-oil soy fabric.

Contact Now

3D Pasta Macaroni Production Line adopts hard wheat flour or corn starch because of the truth the number one material offers a diffusion of second-extruded meals in single-of-a-kind shapes which is probably famous within the market, which incorporates crispy pea, shell, screw, rectangular tube, round tube, wave, and plenty of others. the goods look glittering, translucent easy, and tremendous, and taste delicious after cooking.Functions of Pasta Macaroni Production Line:1).

Contact Now