Features of Puffed Snacks Food Packaging Machine:1. PLC computer control system, Chinese/English touch screen operating system, clearly displaying the working status and operation instructions.2. High-precision servo film transport system, the film is transported smoothly, and with the photoelectric automatic positioning and tracking system, very high positioning accuracy.3. Intelligent digital temperature control system, stable temperature difference control, equipped with tooth sealer to ensure firm sealing.4.

Contact Now

Functions of Granule Packaging Machine:1. It is able to routinely entire bag-making, metering, blanking, sealing, slitting, counting, and printing batch numbers in step with purchaser necessities.2. Advanced microcomputer controller, strong overall performance, smooth adjustment, and accurate detection.Application of Granule Packaging Machine:It's miles appropriate for the packaging of tea, food, shrimp strips, peanuts condiments, and different granular objects.Specification of Granule Packaging Machine:ModelHXK-280Bag length30-170mmBag width30-120mmMeasuring range3-150mlPackin

Contact Now

Capabilities of Granule Packaging Machine:1. It could robotically complete bag-making, measuring, filling, sealing, slicing, counting, stepless speed law, and other features. 2. Easy to regulate and perform. three-aspect sealing is beautiful.3. The configuration of the accessories of this device can whole the features of surprise blanking, date printing, and clean tearing.Application of Granule Packaging Machine:It's far appropriate for computerized packaging of any free, no adhesive, granular materials of nutrition, medicine, and chemical enterprise.

Contact Now

Vertical Form Fill Sealing(VFFS) food packaging machine lends itself to packing and preserving food – using a process called gas flushing to keep products fresh.

Contact Now

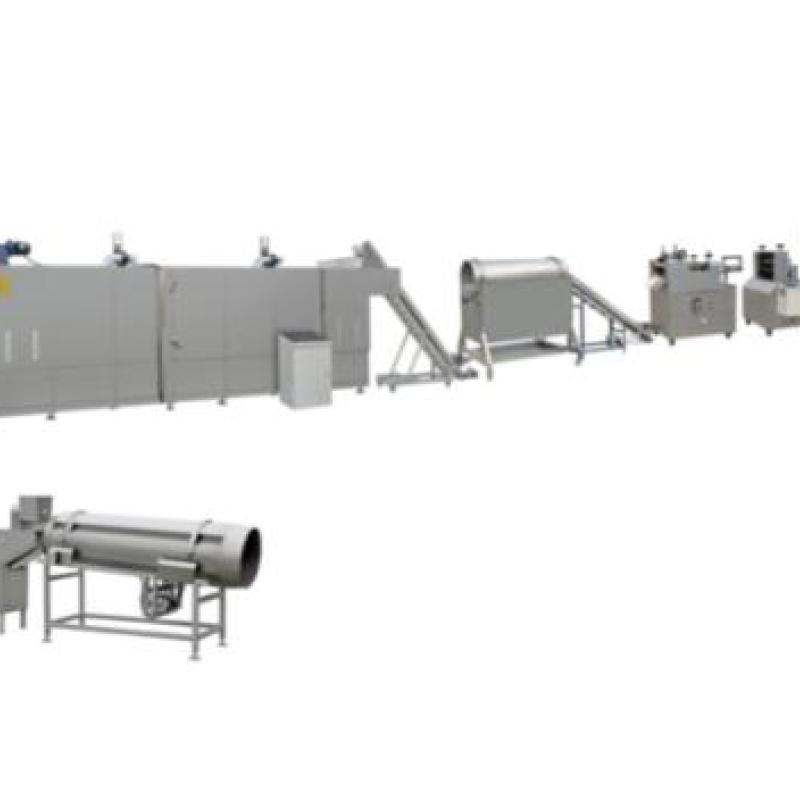

Puffed Corn Snacks Food Making Machine is an advanced and efficient system used in the food industry for manufacturing puffed snacks. It is specifically designed to automate the production process, optimizing efficiency and ensuring consistent quality of the snacks.The machine consists of several key components, each contributing to a smooth and streamlined operation. Firstly, there is a raw material mixer, which blends the necessary ingredients to create the base mixture for the puffed snacks.

Contact Now

Features of Flowpack Packaging Machine:1. Disc kind computerized bedding fabric packing line consists of four parts: a feeding conveyor, a dice sorting gadget, an automated unscramble gadget, and an automated packing gadget. 2. Use of disc centrifugal pressure, to kind which includes stick-shaped material. ship the material so that it will be the automatic unscramble system to find the packing unit. reap non-stop and orderly production, low faulty charge, and delightful packaging effect.Application of Flowpack Packaging Machine:1.

Contact Now

Automatic Grains Granule Packaging Machine consists of: 1. Basic packer2. Ten or fourteen heads weigher3. Z-type conveyor4. Weigher platform5. Finished product conveyorCapabilities of Automatic Grains Granule Packaging Machine:1. Imported percentage complete pc manipulation system, complete Chinese language/English touch display working device, in truth, show the strolling repute and operation commands.2.

Contact Now

Automatic Multi-function Vertical Form Fill Seal Packaging Machine is a popular design for filling materials in small packaging. Automatic Multi-function Vertical Form Fill Seal Packaging Machine consists of:1. Basic packer2. Ten or fourteen heads combined weigher3. Z-type material conveyor4. Supporting platform5. Finished product conveyorWorking principle of Automatic Multi-function Vertical Form Fill Seal Packaging Machine: The VFFS is made of the following sections:1. Dosing system2. Forming area3. Film feeding and alignment4.

Contact Now

Features of Tea bag packaging machine with inner and outer bag:1. Inner and outer bag's movie drawing is managed by way of the stepper motor, solid bag length, and accurate positioning.2. The temperature controller is adjusted by pid to make the temperature control greater accurate.3. Usual gadget movement is controlled by way of %, with the human-system interface show, making sure the fitness of merchandise4.

Contact Now

Functions of Back Sealing Powder Packaging Machine:1. It is able to mechanically complete bag-making, metering, blanking, sealing, slitting, counting, and printing batch numbers consistent with customer necessities.2.

Contact Now

Full Automatic Vertical Granule Packaging Line consists of:1. Basic packer2. Ten or fourteen heads combined weigher3. Z-type material conveyor4. Supporting platform5. Finished product conveyorFeatures of Full Automatic Vertical Granule Packaging Line:1. Imported percent complete pc management system, complete Chinese language/English contact display working device, actually display the running fame and operation commands.2.

Contact Now

Vertical Snacks Granule Packaging Machine Consists of: 1. Basic packer2. Ten or fourteen heads weigher3. Z-type conveyor4. Weigher platform5. Finished product conveyorCapabilities of Vertical Snacks Granule Packaging Machine:1. Imported percentage complete pc manipulation system, complete Chinese language/English touch display working device, in truth, show the strolling repute and operation commands.2.

Contact Now

Puffed Snacks Making MachinePuffed Snacks Making Machine corn powder or flour, vegetable oil, salt, and water due to the truth that the primary raw material uses screw extrusion molding era blended with the shapes of the extrusion die extrusion after which fried to flavored salad, banana chips, pizza quantity realistic shell desserts, cat ears crisp, “snail” a spread of shapes and flavors of fried pasta food, product modeling, the enterprise agency organization is sensitive crisp taste.Extrusion merchandise may be fried, with out drying, the producing way is straightforward, and the small inve

Contact Now

Functions of Automatic Round Corner Powder Packaging Machine:1. The system is appropriate for the food, medicine, chemical industry, and cosmetics industries of powder dimension packing.2. All of the works of bag making, measuring, filling, sealing, reducing, and counting may be achieved routinely, at the equal time, it may also be in keeping with the call for customers to print batch numbers and other functions.3. The contact screen operation, percent control, servo motor to control the bag length, strong performance, smooth to regulate, and correct detection.

Contact Now

Cooking, lowering, and so on strategies to offer spiral, tube, onion ring, waved chips, and so forth snack pellets. consisting of crisp peas, shells, screws, rectangular tubes, spherical tubes, and waves. also can equip with a sample urgent tool and compound device to offer bugles, net crispy, pani puri, and lots of other 3-d snack pellets.

Contact Now

Functions of Automatic Heat Shrinkable Pillow Packaging Machine:1. It's a far horizontal type packing machine, it may automatically complete tubular film bag making, sealing, and reduction automatically. appropriate for packing fixed shape cloth.2. It adopts frequency conversion pace and programmable controller % control. output computerized counting and packing speed robotically prompt pid computerized temperature control, and image-electric powered track computerized manipulate.3. With overload safety, leakage safety, fault alarm, and different superior technology and safety system.4.

Contact Now

Capabilities of Chain Bucket Packing Machine:1. Guide metering of this system, appropriate for packaging sticky, fragile, and slim food.2. Imported % a full pc control machine, human-gadget interface, and contact display for easy and intuitive operation.3. Servo film delivery system, accurate positioning, the first-rate performance of the whole device, and beautiful packaging.4. Perfect computerized alarm safety characteristics to minimize loss.5.

Contact Now

Cat Food Making Machine strains in particular use maize, fish powder, meat powder, and a few meal components due to the precept raw materials, through blending, extruding, roasting, and flavoring to get the very last puffed home canine food.The cat food making machine has been taken care of, one is a dry type dog meals production line, and the opportunity is a moist kind food manufacturing plant, moist type is ready with a boiler that could constantly present warm steam.It may produce all sorts of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach,

Contact Now

Puppy meal manufacturing strains especially use maize, fish powder, meat powder, and a few meal additives because of the major raw materials, via blending, extruding, roasting, and flavoring to get the final puffed doggy food.The pet meals processing line has been sorted, one is a dry type dog food manufacturing line, and the opposite is a wet kind food manufacturing plant, moist type is ready with a boiler that can continuously gift warm steam.It is able to produce all forms of feeds and food as manufacturing floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, and so

Contact Now

Dog Cat Food Making Machine strains especially use maize, fish powder, meat powder, and some meal components due to the main uncooked materials, via blending, extruding, roasting, and flavoring to get the final puffed domestic dog food.The Dog Cat Food Making Machine has been taken care of, one is a dry kind dog food production line, and the opposite is a moist kind meals production plant, wet kind is ready with a boiler that could constantly gift warm steam.It could produce all forms of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog,

Contact Now

Dog Food Making Machine mainly uses maize, fish powder, meat powder, and some food additive as the main raw materials, through mixing, extruding, roasting, and flavoring to get the final puffed pet food.Dog food production line has two types, one is a dry type canine food production line, and the other is wet kind meals manufacturing plant, moist kind is equipped with a boiler that can continuously present hot steam.It may produce all kinds of feeds and meals as manufacturing floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, etc, and pet meals like dog meals, cat fo

Contact Now

Dry Pet Food Making Machine particularly use maize, fish powder, meat powder, and a few meal additives due to the principle raw materials, via mixing, extruding, roasting, and flavoring to get the final puffed home canine meals.The pet food maksing machine has been looked after, one is a dry kind dog food production line, and the alternative is a wet kind meals production plant, moist type is ready with a boiler that would continuously gift heat steam.It may produce all types of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach, bullfrog, and so o

Contact Now

Candy and Bread packaging machine is a horizontal wrapping machine, equipped with an infeed conveyor, a film roller, a fin seal unit, and an end seal unit.

Contact Now

Pet Food Making Machine strains in particular use maize, fish powder, meat powder, and a few meal components due to the precept raw materials, through blending, extruding, roasting, and flavoring to get the very last puffed home canine food.Pet Food Making Machine has been taken care of, one is a dry type dog meals production line, and the opportunity is a moist kind food manufacturing plant, the moist type is ready with a boiler that could constantly present warm steam.It may produce all sorts of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach,

Contact Now