Textured Soy Protein( TSP) is made from defatted soy flour, which is low-oil soy material. so it is plentiful in supply. It is a great source of vegetable protein without all the fat. With muscle structure, it has better absorbency and can defend without cholesterol. It can be boiled at high temperatures with different tastes, or added to meal products as stuffing.

Contact Now

Textured soy protein( tsp) is crafted from defatted soy flour, this is low-oil soy material. so it is ample in delivery. it's miles a splendid supply of vegetable protein without all the fats. with muscle structure, it has higher absorbency and might shield without LDL ldl cholesterol. it may be boiled at excessive temperatures with particular tastes, or brought to meal merchandise as stuffing.

Contact Now

Textured soy protein( TSP) is made from defatted soy flour, which is low-oil soy material. so it's miles plentiful in supply. it's miles an extraordinary supply of vegetable protein without all of the fats. with muscle structure, it has better absorbency and may shield without LDL cholesterol. it is able to be boiled at high temperatures with unique tastes, or brought to meal merchandise as stuffing.

Contact Now

Textured soy protein( TSP) is crafted from defatted soy flour, this is low-oil soy cloth. so it's far plentiful in delivery. it's by far an exquisite supply of vegetable protein without all the fat. with muscle structure, it has better absorbency and might protect without LDL cholesterol. it is able to be boiled at high temperatures with precise tastes, or brought to meal merchandise as stuffing.

Contact Now

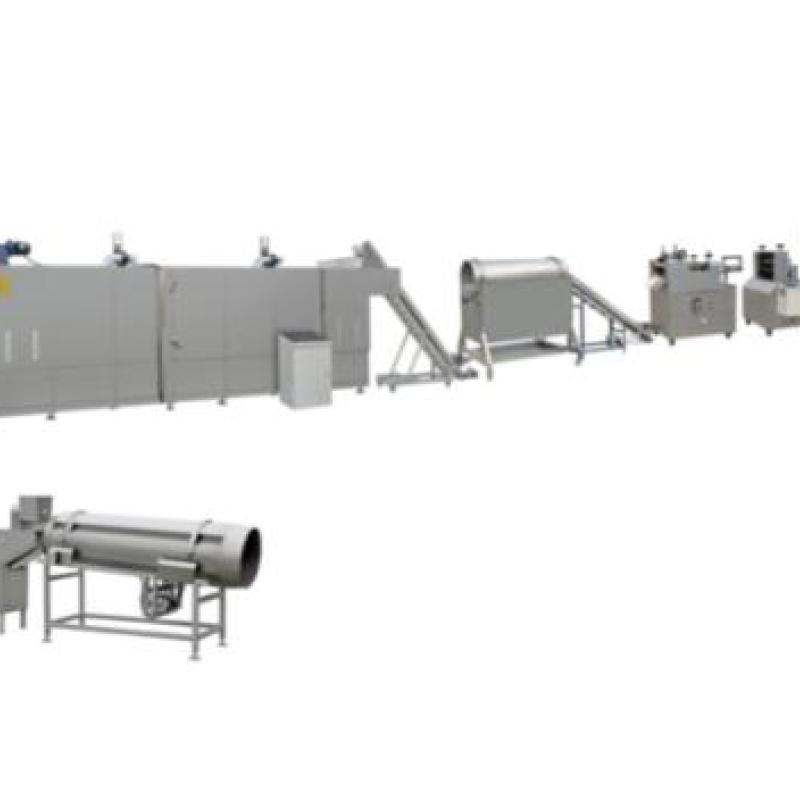

Textured Vegetable Protein( TVP) Food Machine is developed and manufactured on base of our experience combined with advanced machines from foreign countries. The texture of soy protein has high nutrition, looks and tastes like meat, and has a sense of mastication.

Contact Now

Textured vegetable protein(TVP) manufacturing line is evolved and synthetic on the base of our enjoyed mixed with advanced machines from overseas international locations. the texture of soy protein has excessive nutrients, seems and tastes like meat, and has a feel of mastication.

Contact Now

Textured Vegetable Protein( TVP) Production Line is developed and manufactured on base of our experience combined with advanced machines from foreign countries. The texture of soy protein has high nutrition, looks and tastes like meat, and has a sense of mastication. Easy to absorb oil, water, and taste; Textured soybean protein is widely used in the meat products industry, fast food production, deepfreeze food production, and all kinds of vegetarian snacks and food.Textured Soy Protein( TSP) is made from defatted soy flour, which is low-oil soy material. so it is plentiful in supply.

Contact Now

Nutritional Powder Food MachineryNutritional Powder Food Machinery is particularly for corn powder, millet, rice powder, wheat flour, soya meal, lotus root powder, dates powder, sesame, and so on extruding and inflating. Thru extruding, inflating, drying, crushing, and mixing, it could produce many varieties of vitamin powder, such as toddler rice powder, sesame paste, beans powder, and so on. Functions of Nutritional Powder Food Machinery:1). Nutritional Powder Food Machinery should finish the procedures routinely from the feeding to the stop.

Contact Now

Textured vegetable protein(TVP) production line is developed and synthetic on the base of our experience mixed with advanced machines from foreign countries. the texture of soy protein has high nutrients, seems and tastes like meat, and has an experience of mastication. easy to soak up oil, water, and flavor; textured soybean protein is extensively used within the meat products industry, fast meals production, deepfreeze meals production, and all sorts of vegetarian snacks and food.Textured soy protein( tsp) is made from defatted soy flour, that's low-oil soy fabric.

Contact Now

Textured vegetable protein(TVP) manufacturing line is advanced and manufactured on base of our experience blended with superior machines from overseas international locations. They feel soy protein has excessive vitamins, looks and tastes like meat, and has an experience of mastication. clean to soak up oil, water, and flavor; textured soybean protein is extensively used in the meat merchandise industry, speedy meal production, deepfreeze food production, and all varieties of vegetarian snacks and meals.Textured soy protein( tsp) is made from defatted soy flour, which is low-oil soy cloth.

Contact Now

Textured vegetable protein(TVP) production line is advanced and synthetic on the base of our revel in combined with advanced machines from foreign nations. They feel soy protein has excessive nutrition, looks and tastes like meat, and has an experience of mastication. clean to soak up oil, water, and taste; textured soybean protein is extensively used within the meat merchandise enterprise, fast food production, deepfreeze meal manufacturing, and all types of vegetarian snacks and food.Textured soy protein( tsp) is crafted from defatted soy flour, that's low-oil soy fabric.

Contact Now

Pet chews take starch from many types of different materials with medical configurations and emerge as extruded from a co-extruder, it can be made into different kinds of shapes such as stick, bone, bi-color, bi-flavor, twists, middle-filling, and so forth.This form of the meal no longer simplest provides protein, fats, diet, and nutrients for dogs but moreover fulfills the dog nature interest.

Contact Now

Pet chews take starch from many types of different materials with medical configurations and emerge as extruded from a co-extruder, it can be made into different kinds of shapes such as stick, bone, bi-color, bi-flavor, twists, middle-filling, and so forth.This form of the meal no longer simplest provides protein, fats, diet, and nutrients for dogs but moreover fulfills the dog nature interest.

Contact Now

Puppy chews take starch from many varieties of distinctive substances with scientific configurations and become extruded from a co-extruder, it is able to be made into exclusive forms of shapes inclusive of stick, bone, bi-coloration, bi-flavor, twists, core-filling, and so on.This form of food now not simplest provides protein, fats, vitamins, and vitamins for puppies but additionally fulfills the dog nature interest.

Contact Now

Dog chews take starch from many kinds of exceptional substances with clinical configurations and turn out to be extruded from a co-extruder, it is able to be made into one in every of the type styles of shapes which consist of stick, bone, bi-shade, bi-flavor, twists, center-filling, and so forth.This type of meal no longer best offers protein, fat, vitamins, and nutrients for puppies but additionally satisfies the dog nature hobby. it has the subsequent functions: robust tooth, a clean mouth, and enamel. Benefits of Pet Dog Chew Process Line:1.

Contact Now

Pet chews take starch from many kinds of different substances with scientific configurations and become extruded from a co-extruder, it can be made into one of the kind sorts of shapes which include stick, bone, bi-color, bi-taste, twists, center-filling, and so forth.This kind of meal no longer handiest offers protein, fat, nutrition, and nutrients for puppies but also fulfill the dog nature hobby. it has the subsequent features: sturdy enamel, an easy mouth, and enamel. Advantages of Pet Dog Chews Machine:1.

Contact Now

Pet chews take starch from many forms of remarkable substances with clinical configurations and emerge as extruded from a co-extruder, it could be made into one in each of the typical kinds of shapes which encompass stick, bone, bi-shade, bi-taste, twists, middle-filling, and so forth.This sort of meal now not exceptionally gives protein, fat, vitamins, and nutrients for puppies but moreover satisfies the dog nature interest. it has the subsequent features: robust teeth, a smooth mouth, and teeth. Advantages of Pet Chews Making Machine:1.

Contact Now

Puppy chews take starch from many kinds of first-rate materials with clinical configurations and grow to be extruded from a co-extruder, it is able to be made into one in every one of the typical sorts of shapes which encompass stick, bone, bi-coloration, bi-taste, twists, middle-filling, and so on.This type of meal not fantastically gives protein, fat, vitamins, and vitamins for dogs but moreover satisfies the dog nature interest. it has the subsequent functions: robust teeth, a smooth mouth, and a tooth. Benefits of Automatic pet chewing dog cat food production line:1.

Contact Now

Nutritional Rice Making Machine is based on food dietary call for and superior technology. it has the benefits of excessive automatic and saving power.The line is advanced to avoid the lack of nutritional elements within the rice that's made thru conventional rice processing.It adopts rice, millet, black rice, buckwheat, and so on. as important substances. after the approaches of extruding, cooking, and shaping, the substances can be made into bolstered rice, golden rice, buckwheat rice, solanum tubers rice, and so forth.

Contact Now

Instant Rice Quik Cooking Rice Process Line is primarily based on food nutritional call for and superior era. it has the benefits of excessive automatic and saving power.The road is advanced to keep away from the loss of dietary factors inside the rice which is made thru traditional rice processing.It adopts rice, millet, black rice, buckwheat, etc. as foremost substances. after the strategies of extruding, cooking, and shaping, the materials may be made into strengthened rice, golden rice, buckwheat rice, solanum tubers rice, etc.

Contact Now

Macaroni Pasta Making MachineMacaroni pasta making machine only needs to change the mold to process and produce macaroni foods of various shapes, which are very versatile. The macaroni foods produced are high in nutrients and rich in taste, which are deeply loved by consumers. As a staple food, the consumption of macaroni is very large. Therefore, macaroni has a very broad development prospect. And the profit contained in the macaroni industry is also very considerable. The technological process of the Macaroni Pasta Making Machine:1.

Contact Now

Cat Food Making Machine strains in particular use maize, fish powder, meat powder, and a few meal components due to the precept raw materials, through blending, extruding, roasting, and flavoring to get the very last puffed home canine food.The cat food making machine has been taken care of, one is a dry type dog meals production line, and the opportunity is a moist kind food manufacturing plant, moist type is ready with a boiler that could constantly present warm steam.It may produce all sorts of feeds and meals as production floating feeds for aqua, catfish, golden fish, shrimp, crab, loach,

Contact Now

Puffy Snacks Food Packing Machine consists of:1. Basic packer2. Ten or fourteen heads combined weigher3. Z-type material conveyor4. Supporting platform5. Finished product conveyorFeatures of Puffy Snacks Food Packing Machine:1. Imported percent whole pc control gadget, complete Chinese language/English contact show operating tool, in reality, show the jogging fame and operation commands.2. Excessive precision servo movie shipping tool, easy film delivery, with the photoelectric automated positioning monitoring system, excessive positioning accuracy.3.

Contact Now

Puffed Corn Snacks Food Making Machine is an advanced and efficient system used in the food industry for manufacturing puffed snacks. It is specifically designed to automate the production process, optimizing efficiency and ensuring consistent quality of the snacks.The machine consists of several key components, each contributing to a smooth and streamlined operation. Firstly, there is a raw material mixer, which blends the necessary ingredients to create the base mixture for the puffed snacks.

Contact Now