Puffed Corn Snacks Food Making Machine

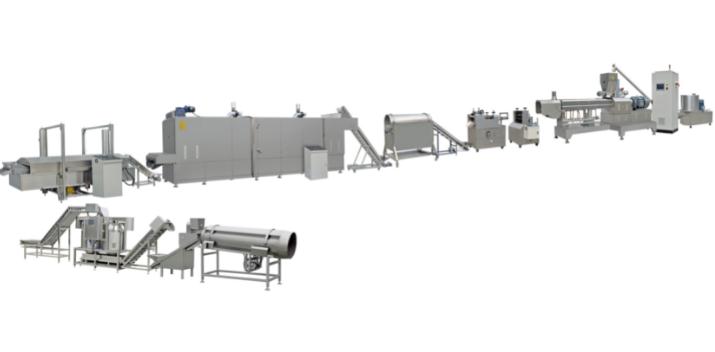

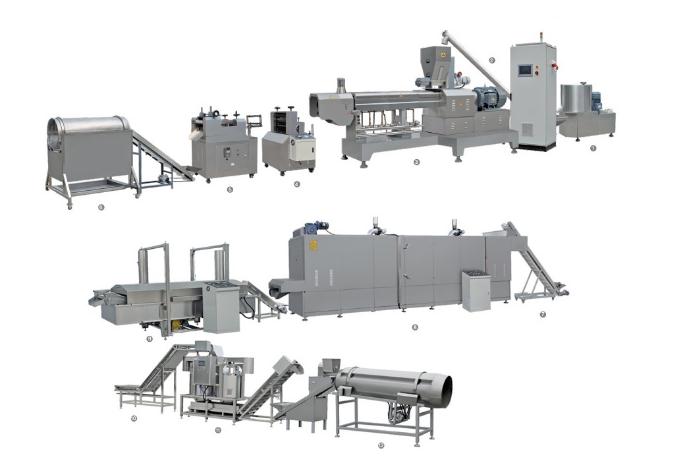

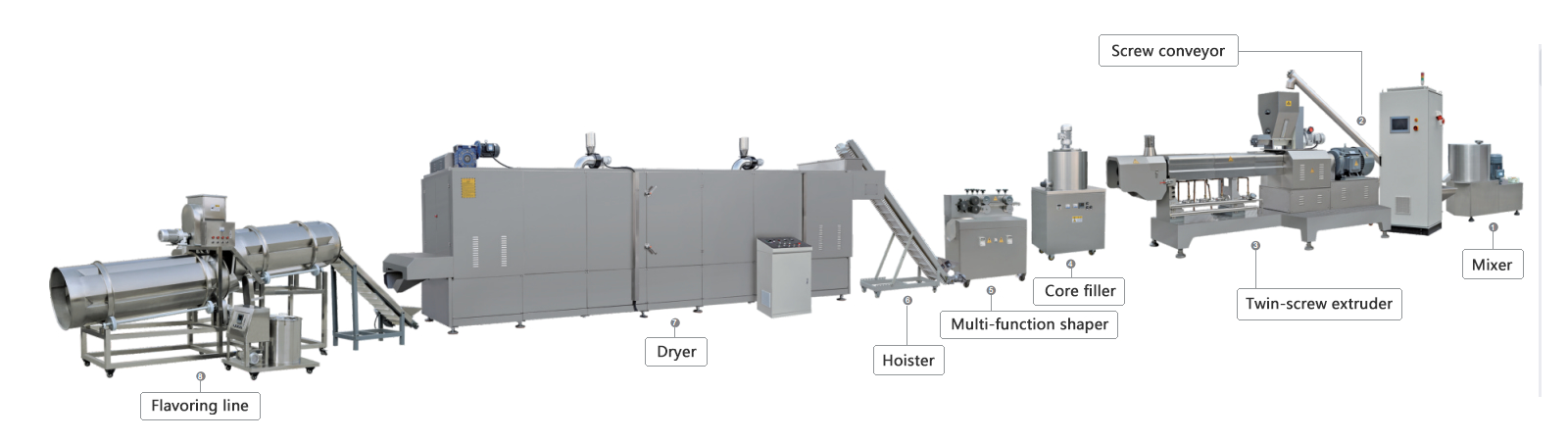

Puffed Corn Snacks Food Making Machine consists of:

1. Mixer

2. Screw elevator

3. Twin screw host/Double screw extractor

4. Embossing machine/Pattern presser

5. Compound shaper

6. Separating machine

7. Hoist/Hoister

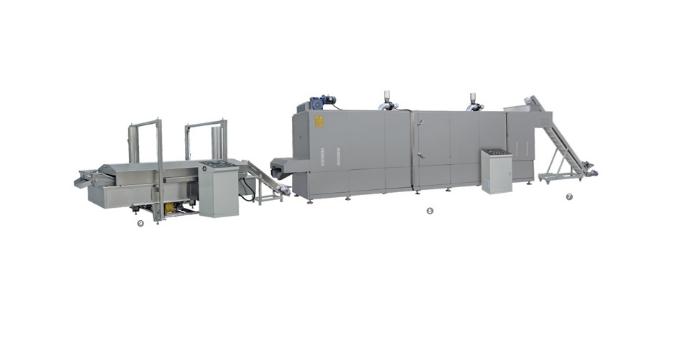

8. Oven/5-layer layer

9. Continuous fryer

10. Hoist/Hoister

11. Oil slinger/De oil machine

12. Automatic flavoring line

Puffed Corn Snacks Food Making Machine is an advanced and efficient system used in the food industry for manufacturing puffed snacks. It is specifically designed to automate the production process, optimizing efficiency and ensuring consistent quality of the snacks.

The machine consists of several key components, each contributing to a smooth and streamlined operation. Firstly, there is a raw material mixer, which blends the necessary ingredients to create the base mixture for the puffed snacks. This ensures that the flavors and ingredients are evenly distributed throughout the product.

Next, the mixture is sent to an extruder, which applies heat and pressure to transform the mixture into a desired shape. The extruder also injects air into the mixture, causing it to expand and form the characteristic puffed texture. The extruder is equipped with various dies and cutting mechanisms to shape the snacks into different forms like rings, balls, or even animal shapes.

After the snacks are formed, they pass through a drying system to remove any excess moisture and enhance their crispness. This step is crucial in ensuring the desired texture and taste of the final product.

Once dried, the snacks move to a seasoning unit, where they are coated with various flavors and seasonings. This can be done using flavor sprays, powders, or even a tumbler system that evenly distributes the seasoning onto the snacks. The seasoning process adds the final touch to the snacks, enhancing their taste and appeal.

Finally, the finished snacks are packaged using either manual or automated packaging equipment. This ensures that the product is protected, preserved, and ready for distribution to consumers.

Overall, the "Puffed Snacks Food Production Line" offers a comprehensive solution for efficient and high-quality production of puffed snacks. It eliminates the need for manual labor-intensive processes, reduces product variability, and increases productivity. This makes it an essential tool for food manufacturers looking to meet the demands of a growing market for puffed snacks.

Specification of Puffed Corn Snacks Food Making Machine:

Model | HX65 | HX70 | HX85 |

Installed Power | 75kw | 135kw | 240kw |

Power Consumption | 55kw | 95kw | 180kw |

Capacity | 120-200kg/h | 200-300kg/h | 400-500kg/h |

Dimension | 28*2.6*2.4m | 36*3.5*3.0m | 38*3.8*3.5m |

Raw materials of Puffed Corn Snacks Food Making Machine:

Wheat flour, potato starch, potato flour, corn starch, cassava starch, etc.

Work Flow of Puffed Corn Snacks Food Making Machine:

Mixer -- Extruder -- Pulling Cutter -- Compound Shaper -- Roller Drum -- Vibration Cooler -- Hoister -- Dryer -- Fryer -- Flavoring

Samples of Puffed Corn Snacks Food Making Machine:

Packaging and shipping of Puffed Corn Snacks Food Making Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation; In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Model | HX65 | HX70 | HX85 |

Installed Power | 75kw | 135kw | 240kw |

Power Consumption | 55kw | 95kw | 180kw |

Capacity | 120-200kg/h | 200-300kg/h | 400-500kg/h |

Dimension | 28*2.6*2.4m | 36*3.5*3.0m | 38*3.8*3.5m |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible