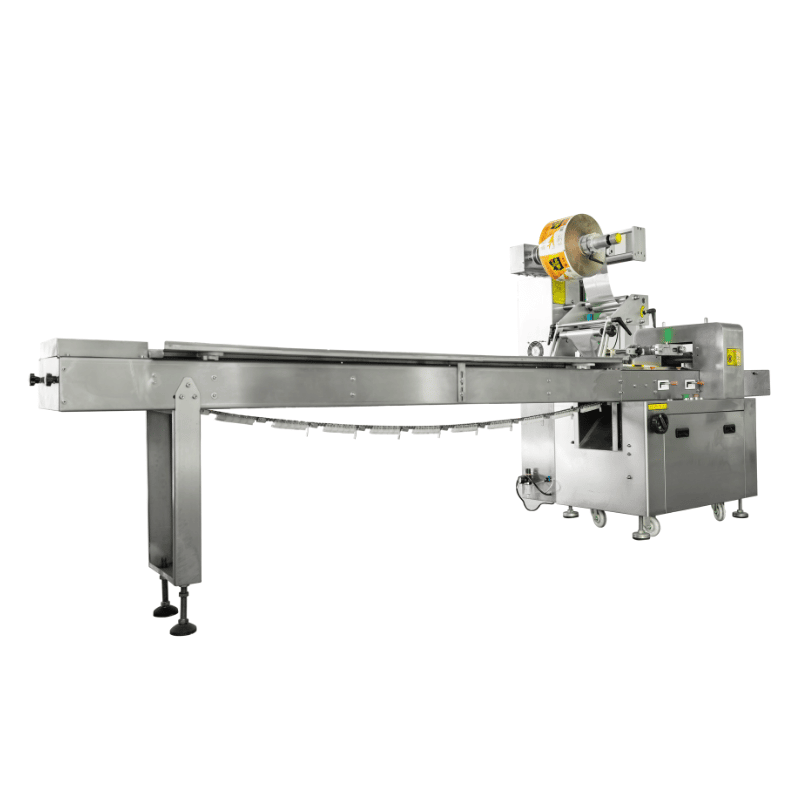

Three Servo Flow Wrapping Machine

Three Servo Flow Wrapping Machine: Three servos motor driven; no product, no pack; auto feeding.

Packing speed: 45-180 bags/min

Bag size: 65-450mm(Length), 30-200mm(Width)

Packing weight: 30-2000g

Power: 2.4/2.7/3.0KW

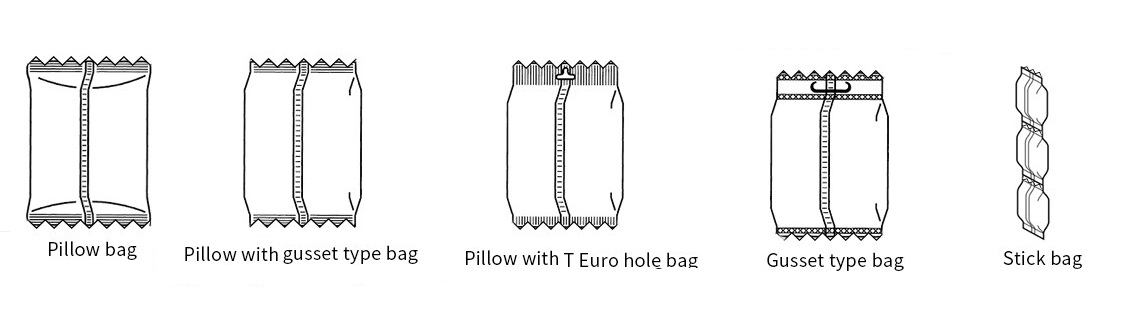

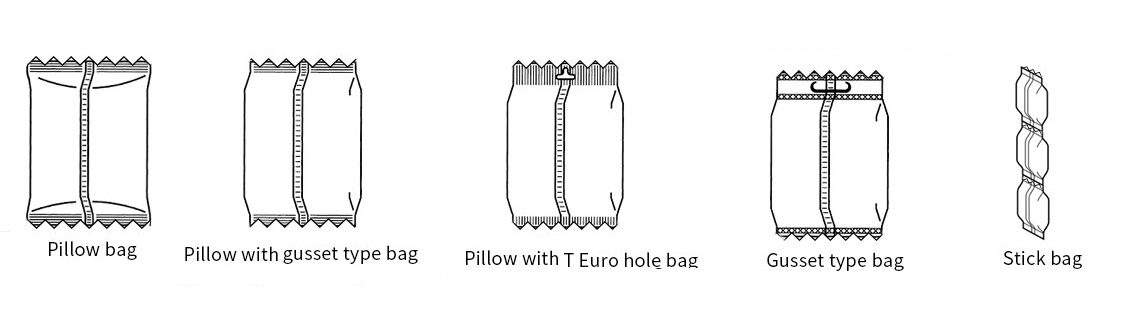

Pouch type: Pillow bag, Pillow with gusset type bag or with T Euro hole bag, Gusset type bag, Stick Bag

Delivery Time: 35 working days.

Payment Term: T/T, L/C, PayPal, Western Union

Packing: Wooden case

Three Servo Flow Wrapping Machine:

1. Three servos motor driven; no product, no pack; auto feeding

2. Photocell sensor, auto tracking for cutting position

3. Film holder with auto-centering device

4. Box motion-type end sealer with hermetic sealing

5. Auto center sealing wheels with pneumatically driven auto engage and disengage

6. Adjustable bag former

7. Gusset fold device

8. Alarm devise for emergency stop

9. MIS (Misplaced Item Skip) device

Optional components of Three Servo Flow Wrapping Machine:

1. Powder coating machine frame.

2. One set of rotary end sealing jaw.

3. One set of auto-centering reel holders.

4. Two sets of center sealers, one cold & one heated.

5. PLC program control.

6. Dancing roller for better tension control.

7. Inverter speed variation.

8. Electronic bag length adjustment device.

9. Photocell for print mark registration.

10. Bag length/bag counting display.

11. Running speed display.

12. Temperature controller.

13. Fixed modular bag forming box.

14. In-feed conveyor & adjustable in-feed guide.

Applications of Three Servo Flow Wrapping Machine:

Bakery, Biscuits & Snacks, Candy & Confectionery, Refrigerated & Frozen Food, Fresh, Shrink Packaging, Wet Wipes / Tissue, Printing Items, Detergents, Pharmaceutical & Medical, Hardware & Tool, Instant Noodles, Miscellaneous.

Bag types of Three Servo Flow Wrapping Machine:

Advantages of Three Servo Flow Wrapping Machine:

1) Compatible with Heavier Packaging

It can pack easier large objects than other types of machines.

2) Optimal Output Capability

It can handle items weighing 10-1,500 grams, 10-1,000 milliliters, or various bespoke weights and volumes.

3) Quick and Easy Maintenance

It can be easily disassembled for cleaning and maintenance so that decreased downtime will keep your production line running smoothly and efficiently.

Specification of Three Servo Flow Wrapping Machine:

| Model | HX-250 | HX-350 | HX-450 |

| Bag making length | 65-300mm | 180-450mm | 180-450mm |

| Bag making width | 30-100mm | 50-180mm | 90-200mm |

| Production height | 5-40 mm | 5-50mm | 10-80mm |

| Packing speed | 45-180bag/min | 45-150bag/min | 45-120bag/min |

| Power specification | 2.4kw/220V, 50/60Hz | 2.7kw/220V, 50/60Hz | 3.0kw/220V, 50/60Hz |

| Overall dimension | 4000x920x1500mm | 4100x1050x1560mm | 4100x1050x1560mm |

| Gross weight | 500Kg | 600Kg | 680 |

Packaging and shipping of Three Servo Flow Wrapping Machine:

We use waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation;

In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

| Three servo motor driven; no product, no pack; auto feeding |

| Photo cell sensor, auto tracking for cutting position |

| Film holder with auto centering device |

| Box motion type end sealer with hermetic sealing |

| Auto center sealing wheels with pneumatic driven auto engage and disengage |

| Adjustable bag former |

| Gusset fold device |

| Alarm device for emergency stop |

| MIS (Misplaced Item Skip) device |

| Three servo motor driven; no product, no pack; auto feeding |

| Photo cell sensor, auto tracking for cutting position |

| Film holder with auto centering device |

| Box motion type end sealer with hermetic sealing |

| Auto center sealing wheels with pneumatic driven auto engage and disengage |

| Adjustable bag former |

| Gusset fold device |

| Alarm device for emergency stop |

| MIS (Misplaced Item Skip) device |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible