Puffing Machine Working Principle

The puffing machine has a pair of screws and sleeves, with the function of mixing and kneading.

After the raw material is in the puffing cavity, the material between the screw sleeve by extrusion, friction, shear, and other effects, its internal pressure rises continuously, reaching 4Mpa, and the temperature rises continuously, up to 140 degrees Celsius. In 3-7s of time, the temperature and pressure rise sharply, and the organization of the material changes, so that the starch furthers paste, protein denaturation, and destruction of crude fiber, killing Salmonella and other harmful bacteria. High temperature and high-pressure material from the outlet, its pressure is suddenly released in an instant, the moisture occurs in a part flash, after cooling the material is loose porous structure, the expansion of the material is dough, flocculent or coarse crumbs.

The structure of the puffing machine:

1. Feeder is to ensure uniform and stable feeding, and according to the rated current value of the extrusion motor to adjust the feeding volume. Generally use an electromagnetic speed control motor or frequency converter to adjust the speed and change the feeder feeding volume. The outlet of the feed hopper is often used to feed the screw churn to the extrusion puffing section.

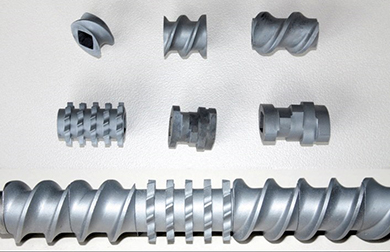

2. The puffing cavity is composed of the screw, screw sleeve, template, card bone, etc. The screw and screw sleeve are combined in sections, you can adjust the degree of compression according to the type of puffed feed and requirements to change the puffing degree of puffed feed.

3. Puffing mechanism according to the role and location in the degree of collapse is divided into 3 segments.

(1) Feeding section: this section of the screw pitch is larger, the main material will be transported and compressed, so that the material is filled with a spiral groove.

(2) Compression section: this section of the screw groove along the direction of the material pushed from deep to shallow, the material is compressed.

(3) Extrusion section: the screw groove is shallower, the pitch gradually becomes smaller, the extrusion pressure can reach 3.0-10Mpa, the temperature can reach 120-150 degrees Celsius, this section of high pressure, high temperature, so the screw, the screw sleeve wear is also serious.

Extrusion section of the outlet for the template, the shape of the template according to the needs of different feeds designed into different die holes, materials from the template of the die hole extrusion, into the atmosphere, the pressure and temperature plunge, so that the volume of rapid expansion, rapid evaporation of water dehydration solidification into the puffed material.

The working principle of extrusion puffing:

Raw materials from the feeder are evenly into the screw extrusion cavity, the space volume of the extrusion cavity along the direction of material advance gradually becomes smaller, and the material is gradually increased by the expansion pressure. At the same time, the material in the extrusion cavity in the process of moving is also accompanied by strong shear, rubbing, and friction. Sometimes, according to the need can also be installed outside the puffing cavity through the electric heating pad auxiliary heating, the result of this common action, so that the material temperature rises sharply, and the material starch paste. The entire material is into a molten plastic gel. The moment the material is discharged from the extrusion die hole, the pressure suddenly drops to 0.1Mpa, the water quickly becomes steam and increases the volume, so that the volume of the material also rapidly expands, and the water vapor further evaporates and escapes to reduce the water content of the material, while the temperature also drops quickly. The material then condenses, and the condensed colloidal material is in many microporous. Continuous extrusion of columnar or flaky puffed products by the rotary cutter cut off after cooling, sometimes also need to dry and spray additives (such as grease, vitamins, etc.) and other post-treatment processes.

Related Products

Submitted successfully

We will contact you as soon as possible