What Is The Working Principle Of Screw Extruder

The powdered raw material containing a certain amount of starch (more than 20%) is treated by the tempering device, so that the moisture of the material reaches 10% ~ 27%, and the temperature rises to 70 ~ 98 ℃. The well-conditioned material enters the screw extrusion chamber, because the volume of the extrusion chamber gradually decreases along the axis, the pressure on the material gradually increases, and the compression ratio can reach 4 ~ 10.

The material is pushed by screw extrusion, accompanied by strong shear and friction, according to needs, it can also be heated through the steam flowing through the barrel jacket, so that the material is in a high temperature and high pressure state, and the starch in the material is gelatinized. When the material is extruded from the die hole by extreme pressure, due to the sudden departure of the body into the atmosphere, the temperature and pressure drop, under the combined action of the pressure difference and the temperature difference, the feed volume expands rapidly, the water evaporates rapidly, the dehydration solidifies, and then is cut into short pellets by the cutter to form an expanded pellet feed.

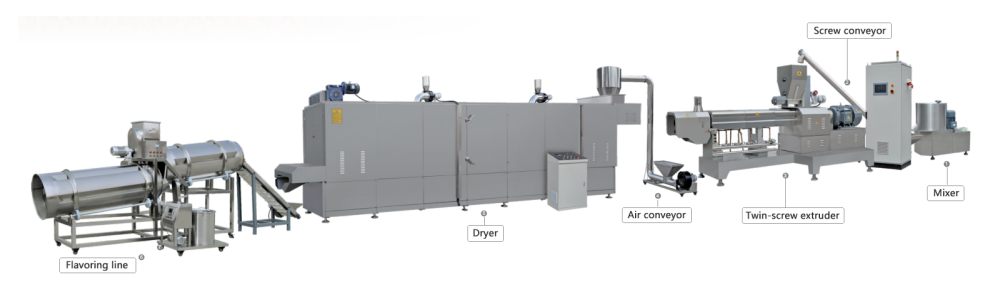

The whole production line because of the production of different extruded feed, so some sections of its processing process may not be the same, but generally have to go through crushing, screening, dosing, mixing, tempering, extrusion, drying, cooling, spraying and finished product packaging and other stages.

Different models have different effects on the swelling effect, such as dry or wet method, yield size, screw length, structure, number of molds and so on. In the production of different formulations of materials due to starch content, due to the starch content and density, the operation technology of oil content, moisture, and crude fiber at different times of production should also be changed accordingly. Our company provides a series of support and assistance to customers from the procurement of raw materials, the provision of formula, the production and installation of equipment, and the training of on-site workers.

Related Products

Submitted successfully

We will contact you as soon as possible