Macaroni Pasta Making Machine

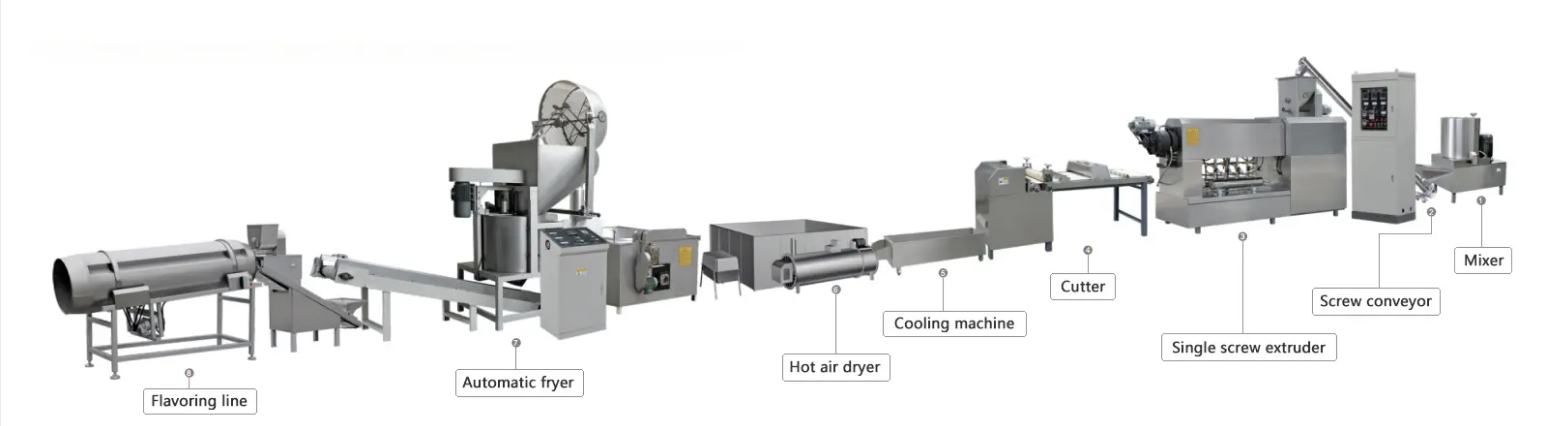

Macaroni Pasta Making Machine consists of:

1. Mixer

2. Screw conveyor

3. Single screw extruder

4. Cutter

5. Cooling machine

6. Hot air dryer

7. Automatic fryer

8. Flavoring line

Macaroni Pasta Making Machine

Macaroni pasta making machine only needs to change the mold to process and produce macaroni foods of various shapes, which are very versatile. The macaroni foods produced are high in nutrients and rich in taste, which are deeply loved by consumers. As a staple food, the consumption of macaroni is very large. Therefore, macaroni has a very broad development prospect. And the profit contained in the macaroni industry is also very considerable.

The technological process of the Macaroni Pasta Making Machine:

1. Long macaroni: First kneading → second kneading → extrusion molding → hanging strips → drying → cooling and cutting → packaging → finished product

2. Short macaroni:

First kneading → second kneading → extrusion molding → drying → cooling → packaging → finished product

In details of Macaroni Pasta Making Machine:

Firstly, select starchy raw materials, including potato starch, corn starch, tapioca starch, wheat flour, and corn flour, etc., and add the appropriate amount of water, salt, etc. to stir in a mixer to mix the raw materials into a dough shape.

Secondly, the long macaroni needs to be kneaded for the second time. A vacuum method is used to remove the air in the dough, so that the noodles that are extruded are more compact and not easy to break, so that the produced macaroni has a higher transparency and a better taste. Short macaroni does not require a vacuum form for the second kneading.

After that, the mixed dough is conveyed into the twin-screw extruder, and the extruder will extrude the dough. At this time, you can choose a variety of different molds, which can produce tubes, strips, letter shapes, thread shapes, etc. shaped macaroni.

Finally, The long macaroni needs to be hung, which is more convenient for subsequent processing. After that, the macaroni is transported into the dryer, and the moisture in the macaroni is quickly lost through high-temperature baking, which can effectively extend the shelf life. The temperature of the macaroni at this time is relatively high, so it is not suitable for direct packaging and needs to be cooled. The short macaroni can be packaged directly using the packaging machine, but the long macaroni needs to be cut into a fixed length before packaging.

Technical Parameters of Macaroni Pasta Making Machine:

Model | HX80 | HX100 |

| Installed Power | 70kw | 100kw |

| Power Consumption | 50kw | 70kw |

| Capacity | 80kg/h | 100kg/h |

| Dimension | 19 × 2.0 × 2.2m | 27 × 2.0 × 2.2m |

Samples of Macaroni Pasta Making Machine:

Packaging and shipping of Macaroni Pasta Making Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation; In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible