Automatic Nuts Granule Packing Machine

Automatic Granule Nuts Packing Machine is suitable to package various freeze-dried fruit, such as dried strawberries, dried apple slices, banana chips, kins of nuts, etc.

Product Name: Nuts Granule Packing Machine

Max. bag width: 200-350mm

Packing speed: 30-60 Bag/Min

Power specification: 3.0/3.5/4.0KW

Delivery Time:35 Working Days

Mode of transport: Shipping by sea

Automatic Granule Nuts Packing Machine

In this feature for packing pulses, the package is fashioned by way of a thermo-sealable film in the form of a roll. relying on the favored stage of automation, the packaging installation can be configured in various ways and could consist of the following composite modules:

- Vertical packaging machine (VFFS)

- Dosing device

- Conveyor

- Printing device

- Transport belt for the ready package

- Metal detector

- Check weigher

Work principle of Automatic Granule Nuts Packing Machine :

Vertical packaging machines (VFFS) are used for the forming, filling, and sealing of plastic bags.

The working method of this machine type is the following:

1. the machine is loaded with a roll of film and will be used for the forming of the final package. the most widely used are thermo-sealable films with single or double layers of PP-PP, PP-PE, PA-PE, and PE-PET.

2. the film is folded to the shape of a sleeve by the package-forming system or the so-called forming collar.

3. The machine draws the formed sleeve downwards, while it concurrently closes the bottom and the vertical seal of the package by heated sealing elements.

4. The machine starts to fill with the product already sealed in the bottom sleeve by the forming collar. The filling with the product is commonly automated by a dosing device (filler). According to the specifics of the product, the machine can be equipped with different types of dosing devices.

5. After the dosed product is placed in the package, which is closed from below, the sealing elements close the upper part of the package (simultaneously closing the bottom part of the next package) and cut the ready package.

Application of Automatic Granule Nuts Packing Machine:

suitable to package various freeze-dried fruit, such as dried strawberries, dried apple slices, banana chips, kins of nuts, etc.

Models of Automatic Granule Nuts Packing Machine:

Depending on the size of the package and the desired capacity, the customer can choose between the following models of vertical packaging machines, appropriate for working with pulses:

Model | HX-420 | HX-520 | HX-720 |

Max. bag width | 200mm | 250mm | 350mm |

Bag length | 50-300mm | 80-350mm | 100-450mm |

Film thickness | 0.04-0.08mm | 0.04-0.08mm | 0.05-0.1 mm |

Packing speed | 30-60bag/min | 30-60bag/min | 10-30bag/min |

Accuracy | <±1-2 | <±1-2 | <±2-3 |

Power specification | 3.0kw/220V,50/60Hz | 3.5kw/220V,50/60Hz | 4.0kw/220V,50/60Hz |

Air consumption | 0.6m2/min | 0.6m2/min | 0.7m2/min |

Overall dimension | 3500x2000x3700mm | 3500x2000x3900mm | 3500x2000x4100mm |

Gross weight | 700Kg | 750Kg | 800Kg |

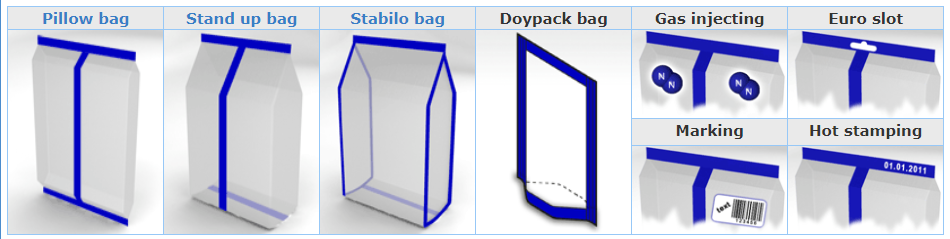

Bag type of Automatic Granule Nuts Packing Machine:

Depending on the desired bag type, the vertical packaging machine is equipped with different types of formers. The bags that could be formed by this type of machine:

Packaging and shipping of Automatic Granule Nuts Packing Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation;

In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible