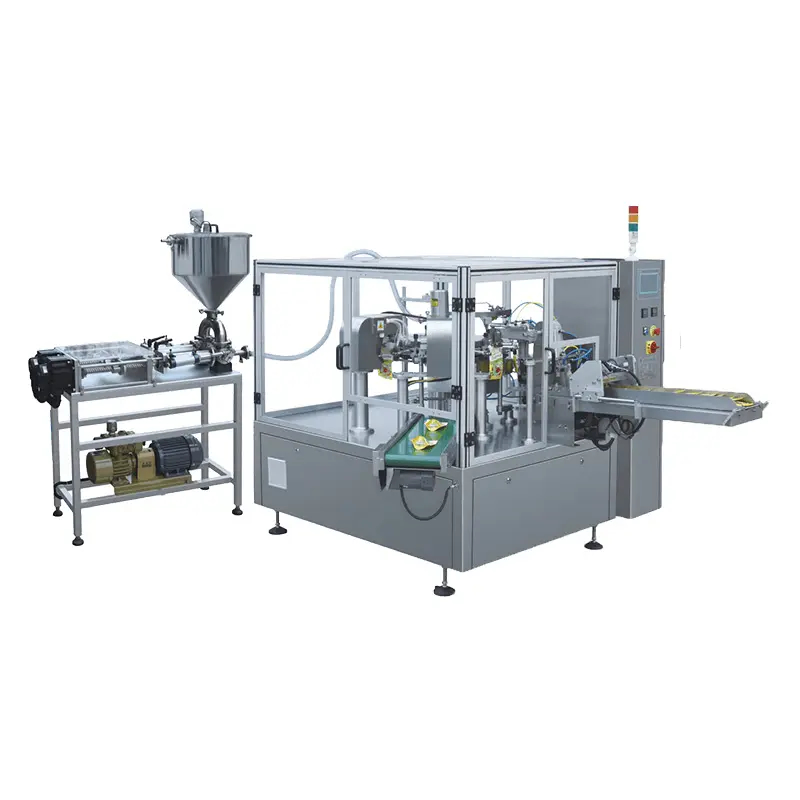

Premade Pouch Packing Machine

Premade Pouch Packing Machine involves filling products in hangable or standalone bags. Built-in weighing and counting technology make sure all doses are accurate.

Packing speed: 40-60 bags/min

Bag size: 100-300mm(Length), 100-200mm(Width)

Packing weight: 50-2000g

Power: 5KW

Pouch type: Pre-made Bag, Stand-up bag, Flat bag, Zipper Bag

Delivery Time: 35 working days.

Payment Term: T/T, L/C, PayPal, Western Union

Packing: Wooden case

Pouch Packing involves filling products in hangable or standalone bags. Premade pouches are filled using auger filling machines – or liquid filling machines. Built-in weighing and counting technology make sure all doses are accurate. Choosing the type of machine depends on the product. Dry powders, superfoods, snack foods, nuts, and the like are packed via an auger filler or vibratory weigher. Liquids are filled using a liquid-filling machine.

Size and finish options of pouch packing:

Pouches can be made to order in almost any size and print finish, including matte, glossy, textured finishes and customizable designs including windows.

Our high-end finish pouches are customizable with branded printing and shop-ready straightly.

With a heat seal at the top of the pouch – to provide tamper – or a ‘euro slot’ for hanging on shop displays.

Features of Premade Pouch Packing Machine

1. Adopt an advanced PLC&Touch screen electrical control system, a friendly man-machine interface, and easy operation.

2. Equipped with a detection device, It can detect when the machine has no packaging or the packaging bag has not been opened.

3. The filling device does not fill, and the heat sealing device does not seal, It avoids a waste of packaging materials and raw materials.

4. Adopt a frequency conversion speed control device, it can be adjusted within a certain range according to needs, and also can quickly change the packaging bag specifications.

Benefits of Premade Pouch Packing Machine:

1. Extremely range-wide, it can be used for paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE composite, etc.

2. low loss of packaging material, prefabricated packaging bags are used.

3. Improving Product grades; perfect patterns can be used on packaging bags and have good sealing quality.

4. Multiple purposes on one machine, and only with different metering devices, it can realize automatic packaging of granules, powders, lumps, liquids, soft cans, toys, hardware, and other products according to different materials.

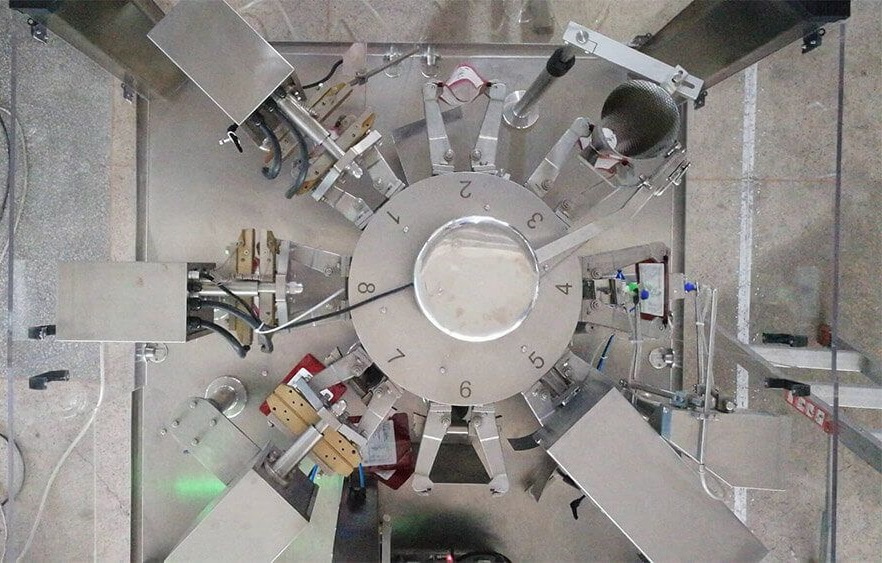

Standard 8 station workflow of Premade Pouch Filling Machine:

1. Feeding Pouch & Pick Up By Gripper

2. Coding & *Open Zipper

3. Pouch Top & Bottom Open

4. 1st Fill

5. 2nd Fill

6. *3rd Fill or * Pre-Heat Seal

7. Heat Seal

8. Embose Seal & Out Feeding

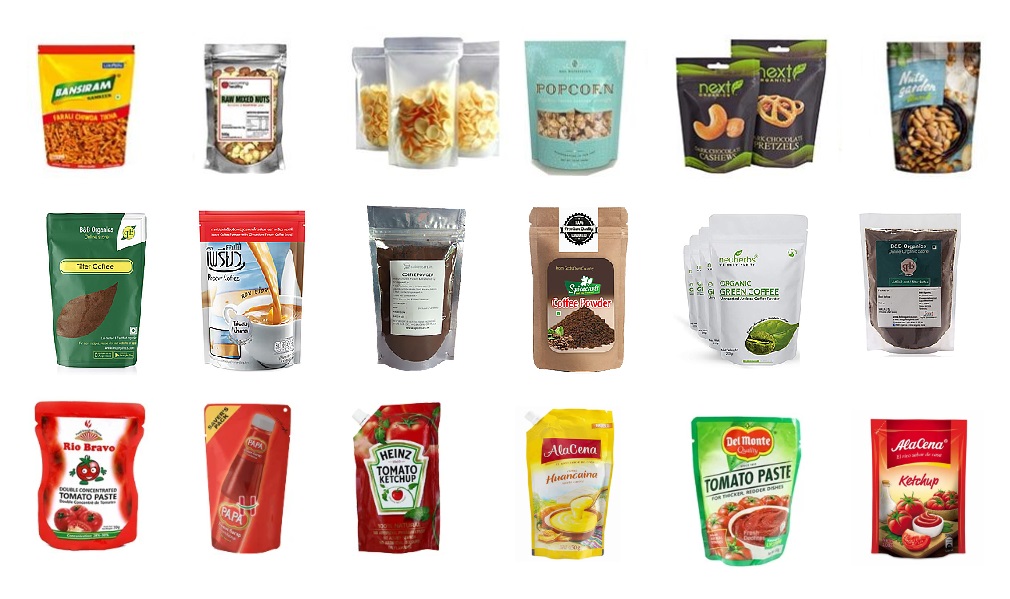

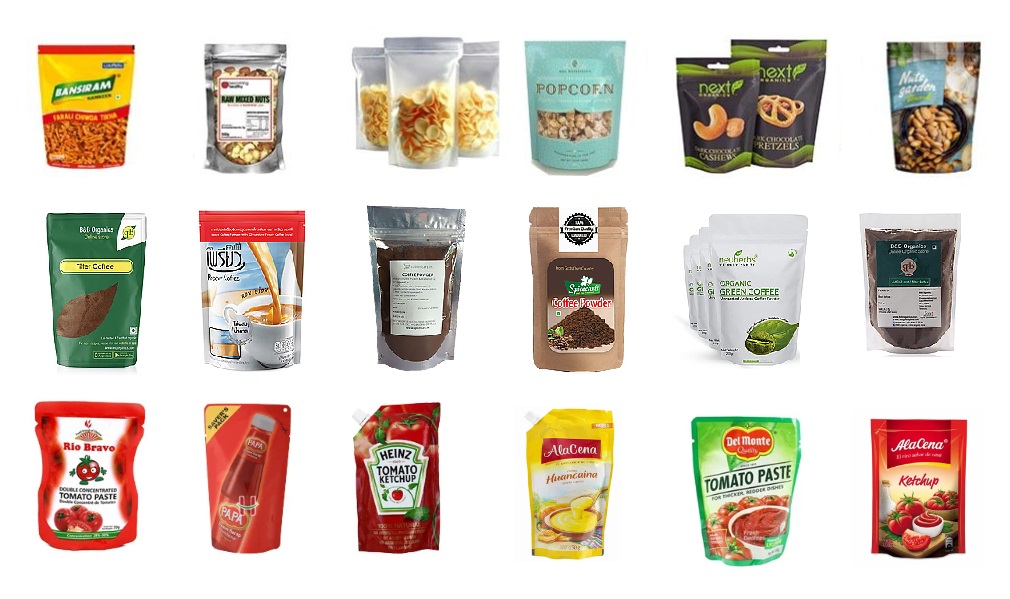

Applications of Premade Pouch Packaging Machine:

1. Food Industry

(1). Snacks: Chips, popcorn, nuts, etc, as they can provide an excellent barrier against moisture and oxygen, keeping the products fresh.

(2). Frozen Foods: Frozen fruits, vegetables, ready meals, etc, offer excellent seal integrity to prevent freezer burn and prolong shelf life.

(3). Liquids and Sauces: Soups, sauces, ready-to-drink beverages, etc, spouted pouches can be filled and sealed using these machines.

2. Pharmaceutical Industry

They can fill and seal pouches for pharmaceutical products like pills, powders, and liquids. And offer superior seal integrity which is crucial in maintaining product efficacy and preventing contamination.

3. Pet Food Industry

Dry kibbles, treats, and wet pet food offer resealable options like zipper closures, ensuring the product remains fresh after opening.

4. Agriculture Industry

Seeds, fertilizers, and other agricultural products can be efficiently packed using premade pouch packaging machines.

5. Cosmetics Industry

Powders, creams, lotions, and other cosmetics can be packaged into small, convenient pouches. Stand up for better display on store shelves.

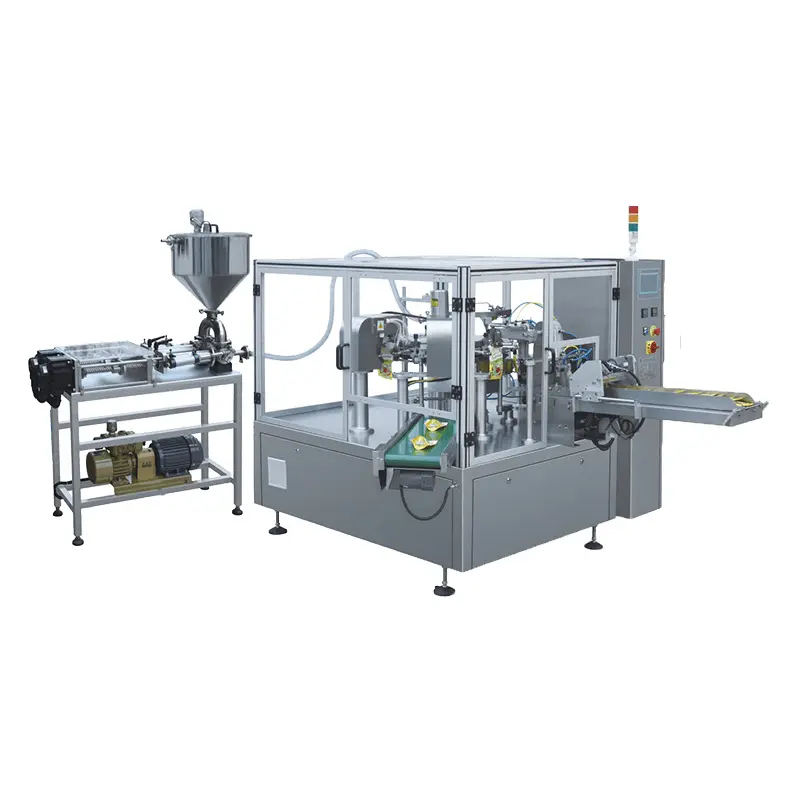

Specifications of Premade Pouch Filling Machine:

| Model | HX-8-200 |

| Line Composition | Basic machine, Ten heads combination weigher, Supporting platform, Product conveyor, Z-type bucket elevator |

| Pouch type | Stand-up bag, Flat bag, Pre-made Bag. |

| Filling speed | 45Bags/Min (The speed depends on the product status and filing weight) |

| Bag size | W:100-200mm L:100-300mm |

| Packing weight | 10-1000g |

| Voltage | three-phase380V 50HZ/60HZ |

| Packing accuracy | <±1 |

| Compressed air consumption | 0.6m3/min |

| Total power | 5KW |

Packaging and shipping of Premade Pouch Filling Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation;

In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible