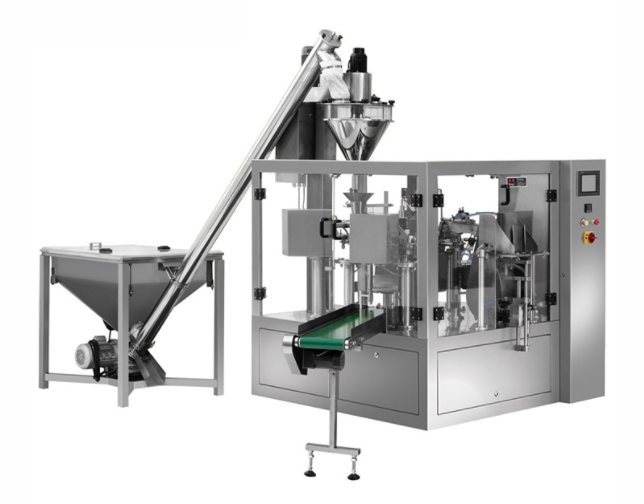

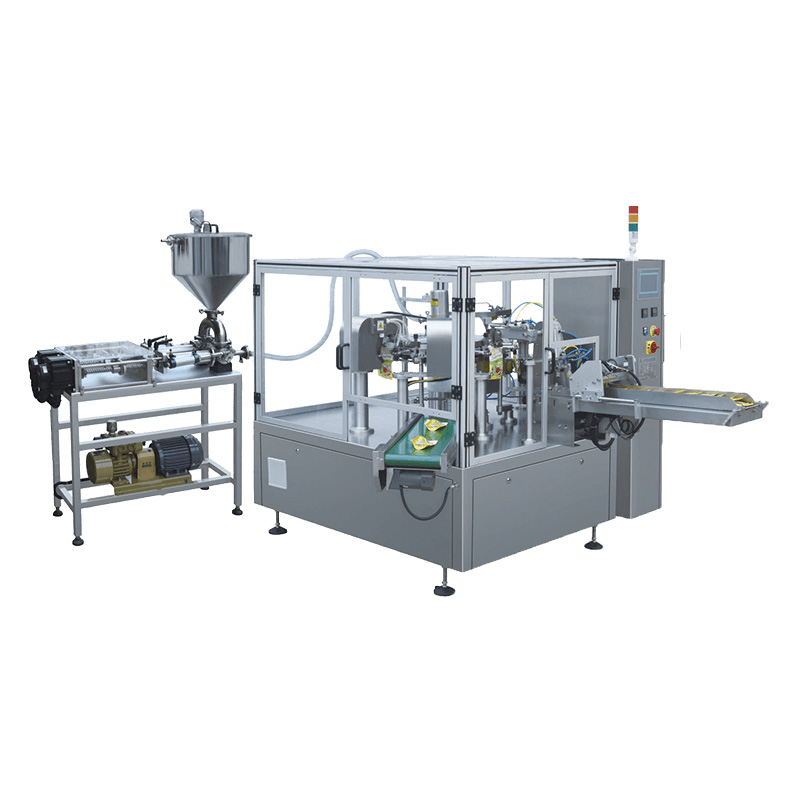

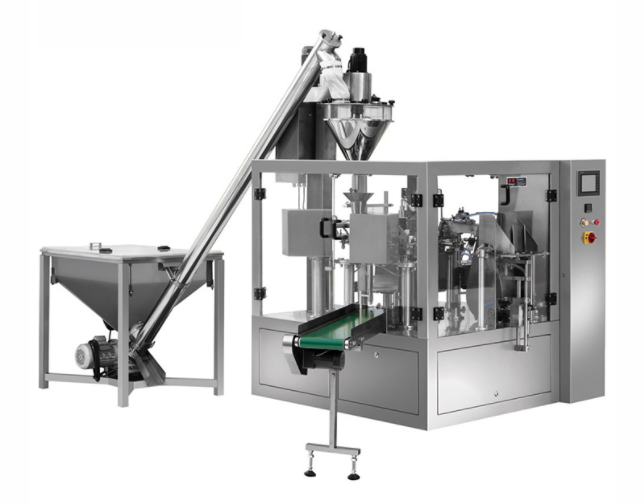

Premade Zipper Pouch Packing Machine

Premade Zipper Pouch Packing Machine is an automatic packing machine that automatic feeding & pick up pouches, coding, open the pouches, fills products into the pouches, then seals & output.

Packing speed: 40-60 bags/min

Bag size: 100-300mm(Length), 100-200mm(Width)

Packing weight: 50-2000g

Power: 5KW

Pouch type: Pre-made pouch, Stand-up pouch, Flat pouch, Zipper pouch

Delivery Time: 35 working days.

Payment Term: T/T, L/C, PayPal, Western Union

Premade Zipper Pouch Packing Machine is an automatic packing machine that automatic feeding & pick up pouches, coding, open the pouches, fills products into the pouches, then seals & output.

Benefits of pouch packing of Premade Zipper Pouch Packing Machine:

1. Cost-effective and eco-friendly methods for preserving products.

2. Save on space and costs when transporting.

3. Up to 30% less material than alternative packing methods, more environmentally friendly.

4. More Popular with consumers due to its resealable function.

5. Free-standing on shelves for increased visibility.

6. More compact and lighter than glass bottles or jars compared with alternative packing methods.

7. Versatile branding options, including colors and printing.

8. Flexible alternative to rigid bottles or cardboard boxes.

Premade Pouch Packing involves filling products in hangable or standalone bags.

Built-in weighing and counting technology make sure all doses are accurate.

Depends on the product. Premade pouches are filled using auger filling machines – or liquid filling machines.

Dry powders, superfoods, snack foods, nuts, and the like are packed via an auger filler or vibratory weigher.

Liquids are packed using a liquid filling machine.

Suited products to pouch packing:

1. Snack foods like nuts

2. Dry powders

3. Capsules and tablets

4. Herbs and spices

5. Glitter

6. Cooking and baking ingredients

Choose from resealable pouches – Air-tight and resealable pouches keep products fresh – including foods and edible liquids. And the robust plastic material prevents odors from leaking through the packaging, to preserve fragrances.

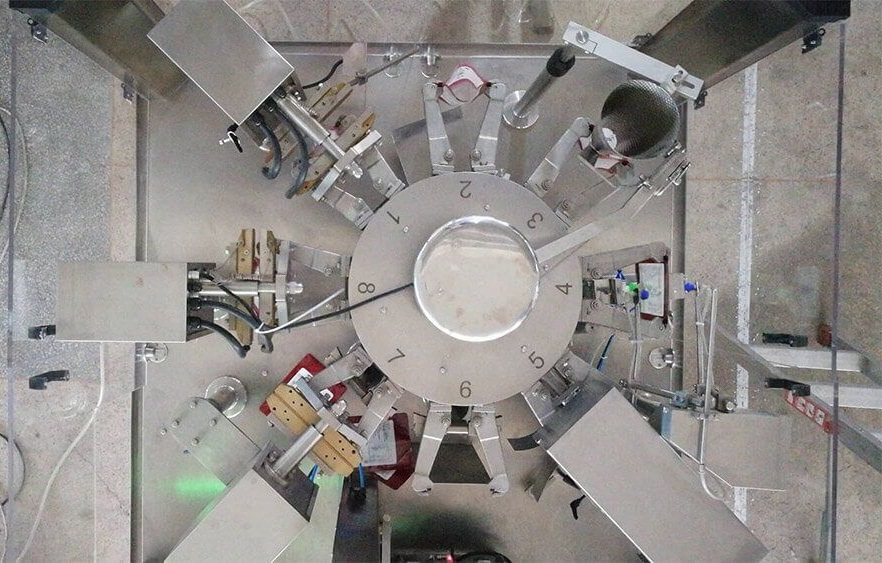

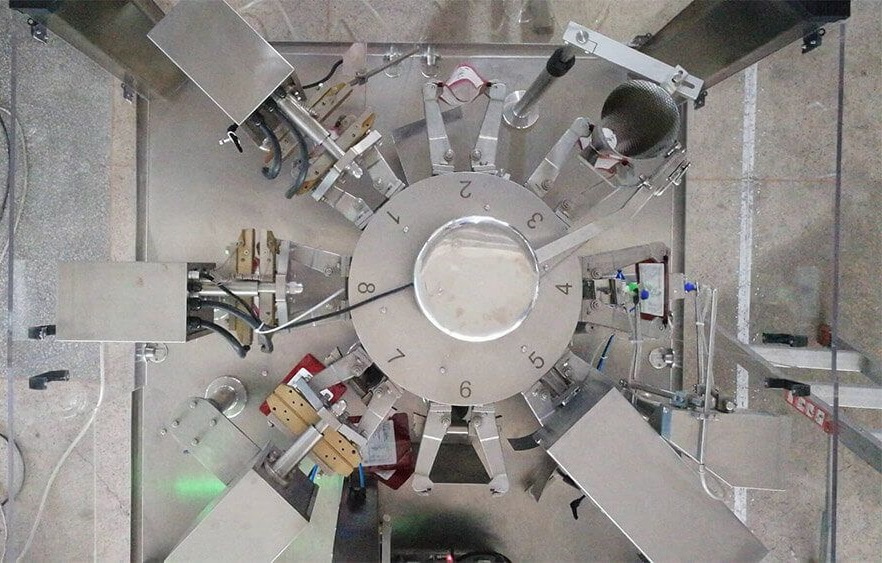

Standard 8 station work process of Zipper Premade Pouch Packing Machine:

1. Feeding Pouch & Pick Up By Gripper

2. Coding & *Open Zipper

3. Pouch Top & Bottom Open

4. 1st Fill

5. 2nd Fill

6. *3rd Fill or * Pre-Heat Seal

7. Heat Seal

8. Embose Seal & Out Feeding

Specification of Zipper Premade Pouch Packing Machine:

| Model | HX-8-200 |

| Line Composition | Basic machine, Ten heads combination weigher, Supporting platform, Product conveyor, Z-type bucket elevator |

| Pouch type | Stand-up bag, Flat bag, Pre-made Bag. |

| Packing speed | 45 bags/Min (The speed depends on the product status and filing weight) |

| Bag size | W:100-200mm L:100-300mm |

| Packing weight | 10-1000g |

| Voltage | three-phase380V 50HZ/60HZ |

| Packing accuracy | <±1 |

| Compressed air consumption | 0.6m3/min |

| Total power | 5KW |

Bag style of Zipper Premade Pouch Packing Machine:

Packaging and shipping of Premade Zipper Pouch Packing Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation;

In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible